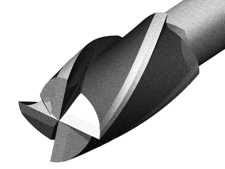

End mills are cutting tools used in industrial milling applications. They feature cutting edges called flutes that require sharp cutting edges and high rake angles. End mills with two or four flutes are common, but some tools have as many as eight flutes to reduce chip loading. Often, end mills are made of harder materials like carbide or cobalt, and are coated to promote tool life at increased cutting speeds.

End mills are cutting tools used in industrial milling applications. They feature cutting edges called flutes that require sharp cutting edges and high rake angles. End mills with two or four flutes are common, but some tools have as many as eight flutes to reduce chip loading. Often, end mills are made of harder materials like carbide or cobalt, and are coated to promote tool life at increased cutting speeds.

For end mill manufacturers, tool geometry and surface finish are critical. Otherwise, these cutting tools can fail prematurely or impart lines and ridges to the workpiece. Micro-burrs that form along the edge of the tool can create stress points, too. For flute polishing, edge radiusing, and surface improvement, NamPower diamond abrasive wheels from Brush Research Manufacturing (BRM) are a smart choice.

Advantages of NamPower Diamond Abrasive Wheels

NamPower diamond abrasive wheels are the ideal solution for polishing the flute reliefs on end mills made of harder materials, including cutting tools with hard coatings. With their composite hub construction, BRM's brushing tools feature a dense, uniform fill pattern that puts more cutting points at the point-of-attack. NamPower diamond abrasive wheels cost significantly less than other diamond wheels on the market, but are built-to-last because of their balanced construction.

NamPower diamond abrasive wheels are the ideal solution for polishing the flute reliefs on end mills made of harder materials, including cutting tools with hard coatings. With their composite hub construction, BRM's brushing tools feature a dense, uniform fill pattern that puts more cutting points at the point-of-attack. NamPower diamond abrasive wheels cost significantly less than other diamond wheels on the market, but are built-to-last because of their balanced construction.

BRM’s NamPower diamond abrasive wheels are also a high-performance, cost-effective choice for edge radiusing, the removal or rounding of sharp edges. With corner radius end mills, a rounded edge on the tips of the flutes can reduce chipping and increase tool life. By conforming to part contours and wiping across end mill edges, NamPower diamond wheels provide the perfect combination of cutting and finishing power.

Choosing and Using NamPower Diamond Abrasive Wheels

NamPower diamond abrasive wheel brushes come standard in 600-mesh diamond for an ultra-smooth final finish. These polishing, edge radiusing, and surface finishing tools are available in three diameters:

- 100 mm (4 inches)

- 150 mm (6 inches)

- 200 mm (8 inches)

As a rule, larger-diameter wheel brushes are less aggressive and more flexible. Smaller-diameter brushes are less flexible and more aggressive. With end mills and other machined parts, the wheel brush’s face width must be wide enough to deburr a wide edge, but also narrow enough to access part recesses that may also need finishing.

Learn More. Get the Brochure.

Proper edge preparation and flute polishing can increase cutting tool life by 200% or more. For flute polishing, edge radiusing, and surface improvement, NamPower diamond abrasive wheels from Brush Research Manufacturing (BRM) are the right choice for end mills and other machined parts made of harder materials. For more information, download the NamPower Diamond Wheel Brush brochure.