Wolfram Manufacturing Inc. makes machined metal parts with complex geometries and fine finishes. Like other job shops, the Austin, Texas manufacturer doesn’t want to send out parts for surface finishing and deburring. When lead times are short and profit margins are tight, outsourcing this work doesn’t make good business sense. Yet many metal fabricators need to meet tight tolerances every time..

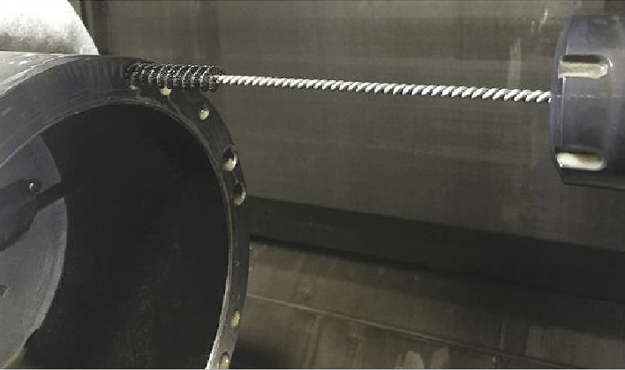

That’s why Wolfram uses the Flex-Hone® from Brush Research Manufacturing (BRM). This Made in the USA metalworking tool mounts readily in the company’s CNC equipment and follows a simple toolpath. The Flex-Hone® removes burrs and surface finish while smoothing the sharp edges in cross-drilled holes. Yet the Flex-Hone® won’t affect part geometry and delivers consistent results across multiple cycles.

Does your company make tight-tolerance parts? Learn more about what you can do with Flex-Hone® tools when you download the article about Wolfram in Manufacturing Engineering magazine.

.