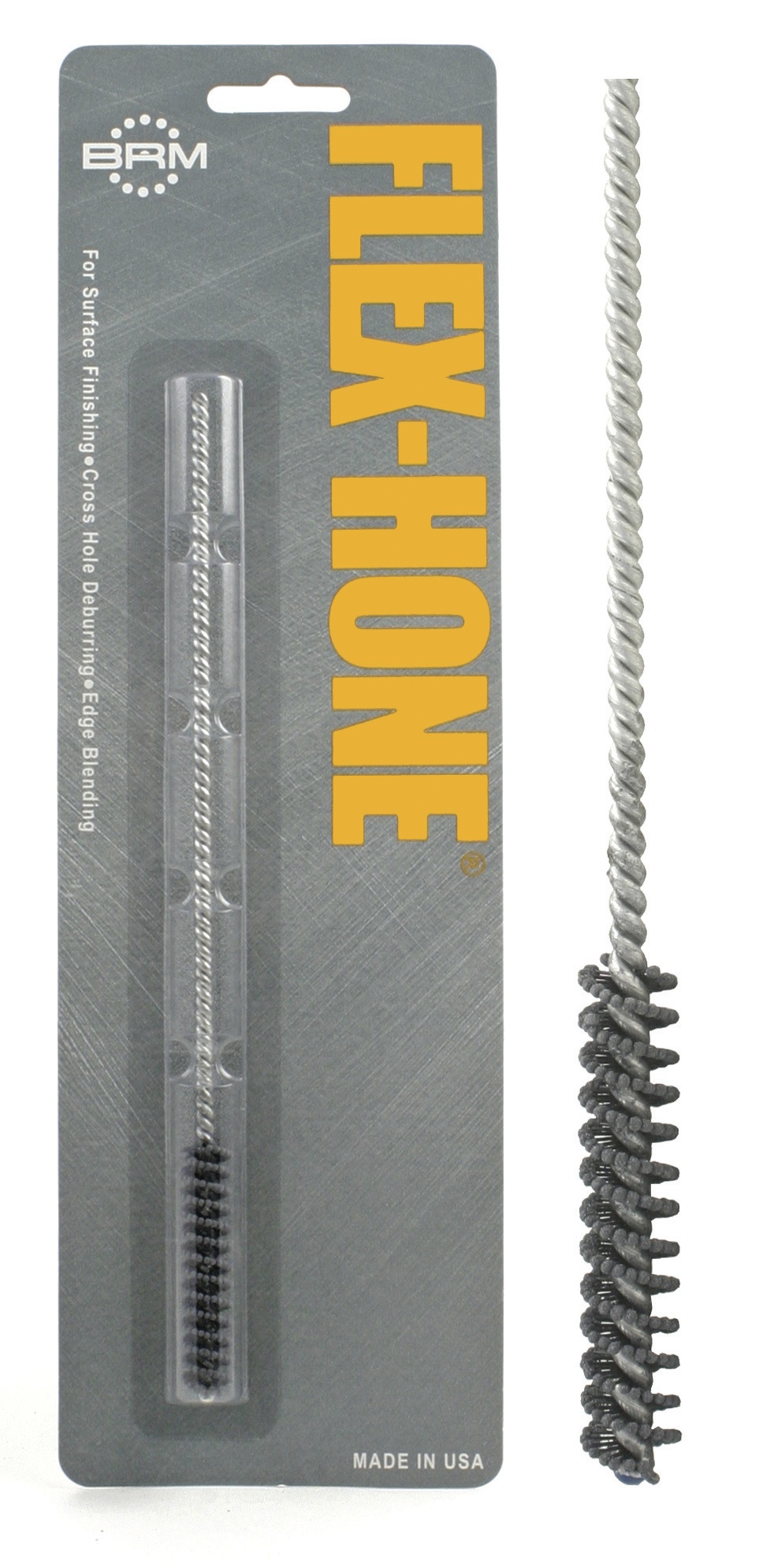

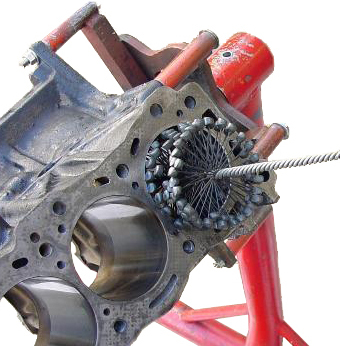

Engine rebuilds are easier when you have the right tools for the job. Brush Research Manufacturing (BRM), a full-line supplier of flexible engine hones and automotive brushes, has the tools and accessories that mechanics need for surface preparation, surface finishing, cleaning, deburring, and cylinder deglazing.

For nearly 60 years, BRM has supplied engine mechanics with high-quality products that are dependable, affordable, and easy-to-use. Let’s take a look at some of the automotive tools and accessories you’ll find in BRM’s product catalog, and that you can order on-line any time.