Diesel Power magazine provides professional diesel mechanics with in-depth examples of engine rebuilds. Do-it-yourselfers (DIYers) also read the world’s largest diesel magazine for tips, techniques, and recommendations about engine tool selection and use.

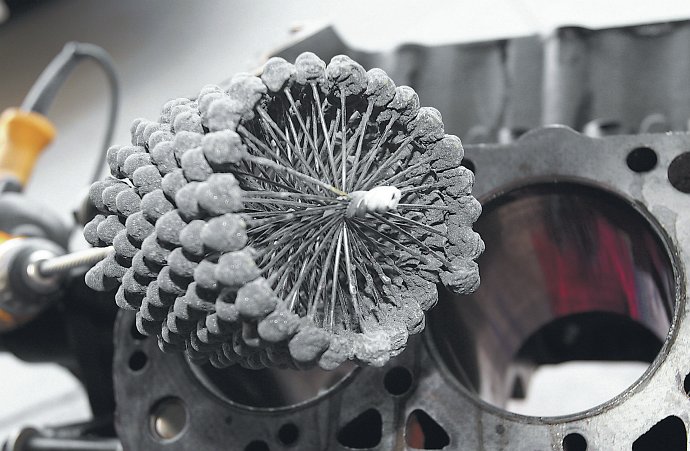

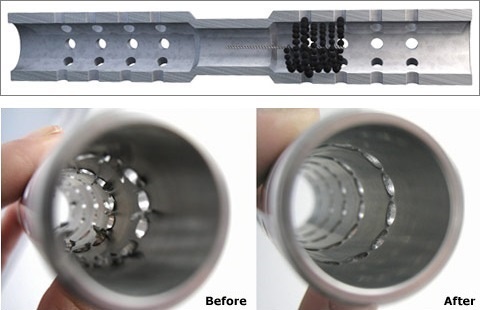

In an article entitled Rebuilding International’s 7.3L IDI Engine Heads and Crank, Diesel Power described what the author called “the key” to a good engine rebuild – the Flex-Hone® tool from Brush Research Manufacturing (BRM). These flexible cylinder hones impart an oil-retaining surface finish that promotes piston ring seating and sealing in big diesel engines like the International IDI.