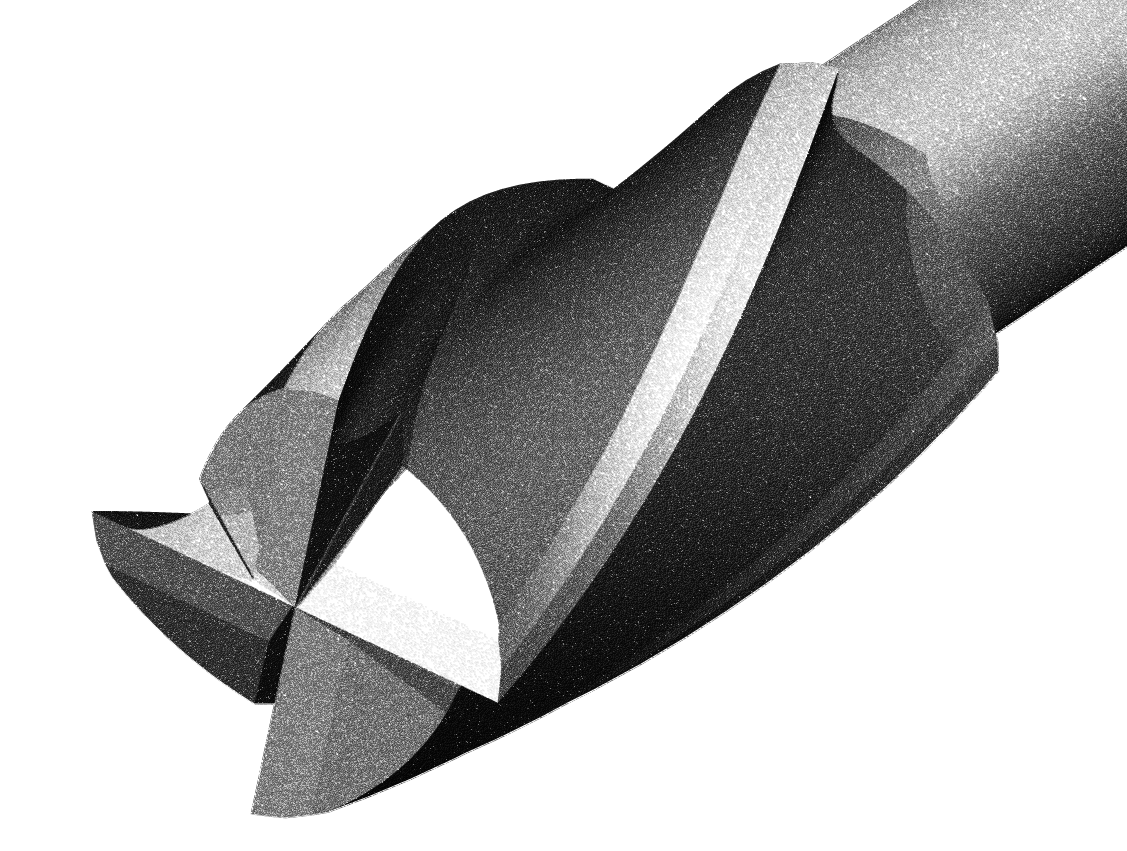

Wheel brushes can remove burrs and improve surface finish, but cutting tool manufacturers need the best tools to get the best results – especially with machined parts made of harder materials.

NamPower wheel brushes with diamond abrasive filaments are the right choice to meet this challenge. They control the edge radius and polish the flue reliefs on cutting tools made of CBN, ceramic, cermet, high-speed steel, and tool steels. NamPower diamond wheels can remove hard coatings like nitride, too.

Today, cutting tool manufacturers are using NamPower diamond wheels to surface finish and deburr parts such as carbide inserts, drill bits, end mills, taps, reamers, gear hobs, and shapes. What do these part manufacturers know about NamPower than can help you save time and money?