Cylinder deglazing breaks the “glaze” or overly-smooth finish on cylinder walls that’s caused by the reciprocating movement of the pistons. In motorcycle and other vehicle engines, a cylinder wall finish that’s free of cut, torn, and folded metal is essential; however, a cylinder wall surface that’s too smooth is also problematic because the piston rings will fail to seat and seal properly.

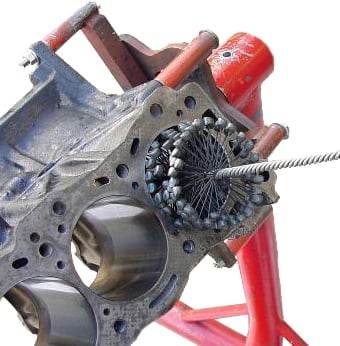

As a pioneer in plateau finishing, Brush Research Manufacturing (BRM) understands that the right way to deglaze an engine cylinder is to impart a series of oil-retaining grooves that optimize lubrication, help reduce engine wear, and promote proper piston ring seating and sealing. The best tool for cylinder wall deglazing is the BRM Flex-Hone®, a flexible, resilient honing tool with abrasive balls or globules.

Flexible Honing Tools and Nikasil Cylinders

Some motorcycle mechanics claim that you can’t deglaze engine cylinders that are lined with Nikasil, a high-performance plating material that’s designed to reduce engine friction and wear. Because Nikasil coatings are thin, these engine mechanics say, rigid honing tools can remove too much of the cylinder liner and require Nikasil replating.

That may be a problem with rigid cylinder hones, but flexible honing tools aren’t designed for heavy-duty material removal. Instead, BRM’s engine hones use a soft, cutting action to deglaze the cylinder walls and impart a plateau finish – even with very hard materials such as Nikasil. Note, however, that Flex-Hone® tools are not recommended for use with ported Nikasil cylinders.

Facebook and Flexibles Hones

At on-line forums across the Web, Flex-Hone® users have documented their successful use of BRM glaze breaker hones with Nikasil cylinders in motorcycles made by BMW, Kawasaki, Yamaha, and others. BRM’s Facebook page is also a place where motorcyclists and mechanics can swap stories, ask questions about cylinder deglazing, and get answers about flexible cylinder hones.

Recently, a motorcyclist from the United Kingdom messaged us about cylinder deglazing and Flex-Hone® selection. As the BRM Team explained, flexible hones are supplied in an oversized condition, but should be ordered by the nominal bore diameter. If the bore size is between two Flex-Hone® sizes, then choose the larger-diameter tool. Cylinder honing tools are available for bores ranging from 4 mm - 36 inches.

Learn More. Get the Guide.

Tool diameter is an important Flex-Hone® specification, but it’s hardly the only one. When the U.K. motorcyclist asked us which abrasive type to select, the BRM Team explained that aluminum oxide (AO) is typically used with Nikasil cylinders. Ideal grit selection is based on the piston ring manufacturer’s surface finish specifications, but most users select BRM’s 240-AO Flex-Hone® tool.

Are you a motorcyclist or an engine mechanic? Do you have questions about deglazing engine cylinders? BRM's Flex-Hone Resource Guide is a free, downloadable resource that puts important technical information right at your fingertips. Download the Flex-Hone Resource Guide today.