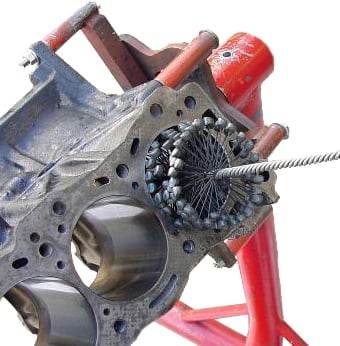

Flexible honing for engine cylinders imparts a plateau finish that optimizes lubrication and reduces friction and wear. Flexible cylinder honing also removes cut, torn, and folded metal that can interfere with the operation of mechanical components such as piston rings. By removing burrs, imparting a series of oil-retaining grooves, and reducing raised areas to a uniform height, BRM Flex-Hone® tools impart the ideal surface finish. Two automotive application guides explain the benefits of flexible cylinder honing for the automotive aftermarket.

Flexible Cylinder Hones for Field Equipment Repairs

Would you rather spend $30,000 to replace damaged cylinders, or would you rather repair them with a tool that costs less than $200 and is easy-to-use? If you offered this choice to your customers, what would they say? Would they happily spend thousands of dollars to replace equipment they’d never even used, or would they give your company credit for solving a surface finishing problem in a smart, efficient, cost-effective way?

Would you rather spend $30,000 to replace damaged cylinders, or would you rather repair them with a tool that costs less than $200 and is easy-to-use? If you offered this choice to your customers, what would they say? Would they happily spend thousands of dollars to replace equipment they’d never even used, or would they give your company credit for solving a surface finishing problem in a smart, efficient, cost-effective way?

Ask Elmar Industries, a manufacturer from Depew, New York that makes filling machines for sanitary applications. Elmar’s rotary piston equipment is a shining example of precision machining. The company’s 45-station piston filler dispenses a metered quantity of product, and the tolerance between each valve and valve housing must be within 0.001 in. Elmar manufactures filling machinery to the highest quality standards, but equipment suppliers can’t control accidents that happen on a customer’s factory floor.

Topics: Cylinder Honing

Cylinder deglazing breaks the “glaze” or overly-smooth finish on cylinder walls that’s caused by the reciprocating movement of the pistons. In motorcycle and other vehicle engines, a cylinder wall finish that’s free of cut, torn, and folded metal is essential; however, a cylinder wall surface that’s too smooth is also problematic because the piston rings will fail to seat and seal properly.

Topics: Cylinder Honing, Motorcycle Engines