Wolfram Manufacturing Inc. makes machined metal parts with complex geometries and fine finishes. Like other job shops, the Austin, Texas manufacturer doesn’t want to send out parts for surface finishing and deburring. When lead times are short and profit margins are tight, outsourcing this work doesn’t make good business sense. Yet many metal fabricators need to meet tight tolerances every time..

Flex-Hone® for Tight-Tolerance Parts Saves Manufacturer Time and Money

Topics: Flex-Hone, surface finishing, deburring, machined parts

Flex-Hone® Reduces Roughness and Promotes Sealing in Anodized Cylinders

Anodizing imparts a wear-resistant coating to cylinders. This electrochemical process permits the use of lightweight aluminum instead of heavier metals, but anodizing increases surface roughness. Moreover, anodizing increases a cylinder’s outer diameter (OD) while decreasing its inner diameter (OD). These changes in surface quality and dimensions can interfere with parts mating and sealing.

Topics: Flex-Hone, surface finishing, anodized cylinders

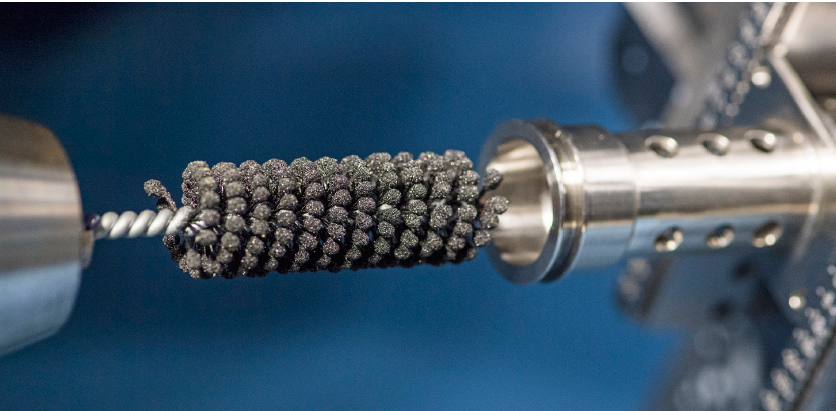

Machined Superalloys Get Better Surface Finishing Tools

High-nickel, iron, and cobalt alloy steels are difficult to machine. These superalloys expose cutting tools to so much stress, strain and heat that tool edges can begin to lose their hardness. When that happens, heavy burrs won’t break off cleanly and work hardening may occur. As Metalworking World magazine explains, outsourced surface finishing may seem like the only option – but that's not the case.

Topics: Flex-Hone, cbn flex-hone, surface finishing, machined superalloys