Cross-hole deburring is an essential finishing operation for precision metal parts. In engine and transmission components, cross-drilled holes serve as conduits for fluids, lubricants, and greases. If burrs block these passageways, problems can result. Metal burrs in cross-drilled holes can also affect dimensional tolerances and lead to part misalignments.

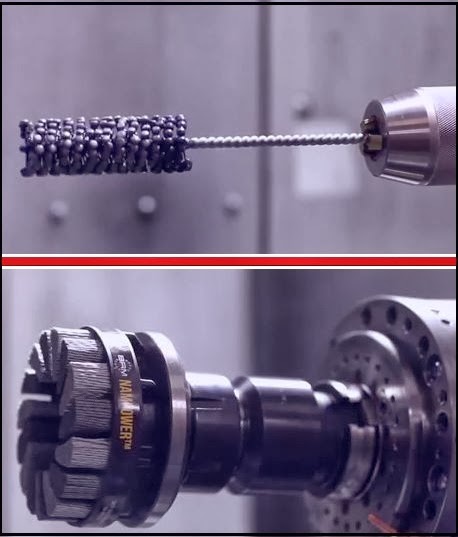

Manual cross-hole deburring can be time-consuming. Manufacturers and machinists can outsource deburring operations instead, but this adds time and costs to precision metal parts. That’s why in-house, automated cross-hole deburring is an attractive, cost-effective alternative. With BRM Flex-Hone® tools, you can use your own CNC machinery or other production equipment to get great results.