Brush Research Manufacturing (BRM) supplies many different Flex-Hone® tools for surface finishing and deburring small-diameter cylinders. These flexible cylinder hones are grouped into BC and Diamond Flex-Hone® categories, and then specified by tool diameter, abrasive type, and grit size or mesh.

Brush Research Manufacturing (BRM) supplies many different Flex-Hone® tools for surface finishing and deburring small-diameter cylinders. These flexible cylinder hones are grouped into BC and Diamond Flex-Hone® categories, and then specified by tool diameter, abrasive type, and grit size or mesh.

All Flex-Hone® tools are Made in the USA and can be ordered via BRM's website or through our vast network of national distributors. These surface finishing and deburring tools are also available through the American-owned company’s global distributor network as well. So which small-diameter Flex-Hone® tools do you need? Let's take a look at BC Series and Diamond Flex-Hone® tools, and examine how to order and use them.

BC Series Flex-Hone® Tools

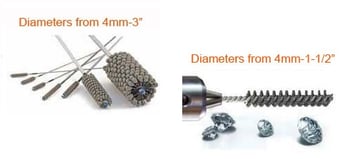

BC Series Flex-Hone® tools are designed for cylinder bores from 4mm (0.157”) to 3” (76.2mm) in diameter. Applications include surface finishing and cross-hole deburring for brake, wheel, hydraulic, and pneumatic cylinders to name just a few. These flexible cylinder hones are also the right choice for small-diameter cylinders such as valve guides. As the Kart Racing Flex-Hone® Application Guide explains, BC Series tools are even used to improve cylinder wall surface finish in the engines of small four-wheeled vehicles called Karts.

BRM supplies BC Series Flex-Hone® tools in 7 standard abrasive types:

- silicon carbide (SC)

- aluminum oxide (AO)

- 25% zirconia / 75% alumina (Z25)

- 40% zirconia / 60% alumina (Z49)

- boron carbide (BC)

- tungsten carbide (WC)

- levigated alumina (LA)

Grit sizes range from 20 to 800. Additional abrasive types and grit sizes are available upon request. As a rule, the base material of the workpiece determines which abrasive to use. The degree of surface improvement that’s required determines the grit selection. Download the Flex-Hone® Resource Guide for details.

Diamond Flex-Hone® Tools

Diamond Flex-Hone® tools are designed for deburring, edge blending, and surface finishing harder materials. Examples include carbide wear parts, guide and drill bushings, ceramic cylinders, heat-treated steel, and high-nickel stainless steel. Diamond Flex-Hone® tools are also used to deburr, edge blend, and surface finish aerospace components, medical parts, chromed and plated bores, and EDM recast layers.

BRM supplies Diamond Flex-Hone® tools for cylinder bores from 4mm (0.157”) to 38mm (1.5”). Sizes larger than 22mm are available by special order. All diamond tools come in three mesh sizes: 170/200, 800, and 2500. By using BRM diamond tools in progressively finer grits, users can create a near-mirror finish with a very low RA. The diamond crystals in BRM’s flexible honing tools have self-sharpening edges. Additional benefits include rapid cut-rates and free-cutting. Download the Diamond Flex-Hone® Brochure to learn more.

How to Use Small-Diameter Flexible Hones

The BRM Flex-Hone® is a low RPM tool. Tool diameter and application requirements determine your specific operating parameters. The Flex-Hone® Resource Guide provides general speed ranges based on tool diameter, but machine trials are necessary. Small-diameter Flex-Hone® tools are designed for use with most any rotating spindle, including handheld electric drills and production machinery.

As a rule, smaller hones run at faster speeds. For example, the suggesting operating speed for a 1”-diameter Flex-Hone® is 800 RPM. Ball hones with a 3” diameter run at slower operating speeds, typically 700 RPM. Always use flexible cylinder hones with a high-quality lubricant such as Flex-Hone® oil, and rotate the tool in a clockwise direction prior to entering the cylinder

Talk to BRM at WESTEC About Flex-Hone® Tools

Are you ready to learn more about small-diameter Flex-Hone® tools for cylinder deburring, edge blending, and surface finishing. Then visit BRM at WESTEC 2015 in Booth #2309 this week. Even better, request a meeting in advance. Small-diameter cylinders don’t have to be a big problem, so talk to the BRM Technical Team about BC Series and Diamond Flex-Hone® tools while you're at WESTEC.