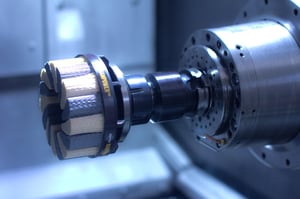

For automated deburring and surface finishing, NamPower disc brushes get great results. Made by Brush Research Manufacturing (BRM), these industrial brushing tools feature nylon abrasive filaments with a unique combination of ceramic and silicon carbide abrasive. By conforming closely to part contours, the brush tool’s filaments work like flexible files for maximum burr removal rates and a superior surface finish.

For automated deburring and surface finishing, NamPower disc brushes get great results. Made by Brush Research Manufacturing (BRM), these industrial brushing tools feature nylon abrasive filaments with a unique combination of ceramic and silicon carbide abrasive. By conforming closely to part contours, the brush tool’s filaments work like flexible files for maximum burr removal rates and a superior surface finish.

BRM supplies NamPower disc brushes in different styles, trim lengths, grit sizes, and tool diameters. The NamPower Resource Guide provides complete information about tool selection and operating parameters, but users may have questions about how to increase or decrease brush aggression, achieve a finer or coarser surface finish, contour parts, or avoid smears.

Here’s what you need to know – and how you can improve deburring with NamPower disc brushes.

Brush Aggression

All NamPower disc brushes provide reliable, cost-effective, and consistent results. Individual tools vary in terms of aggressiveness, however, so NamPower disc brush users need to consider the following factors during brush selection and use.

All NamPower disc brushes provide reliable, cost-effective, and consistent results. Individual tools vary in terms of aggressiveness, however, so NamPower disc brush users need to consider the following factors during brush selection and use.

For more aggressive brushing action, choose a NamPower disc brush with these characteristics.

- Shorter trim length

- Larger diameter

- Coarser grit size

- Higher-density fill (turbine style)

Then, when using this brush tool, increase the spindle speed and the cut depth.

For less aggressive brushing action, choose a NamPower disc brush with these characteristics instead.

- Longer trim length

- Smaller diameter

- Finer grit size

- Medium-density fill (dot style)

Then, when using this brush tool, increase the pressure.

Finer or Coarser Finishes

NamPower disc brush users also need to follow some basic guidelines to achieve a finer or coarser surface finish, depending on the application requirements. Here’s what you need to keep in mind:

- For finer finishing, choose a NamPower disc brush with a longer trim length. Use a coolant during brushing and increase the spindle speed, too.

- For coarser finishing, choose a NamPower disc brush with a smaller-diameter and a larger grit size. During brushing, reduce the spindle speed and avoid the use of a coolant.

Contour Parts and Avoid Smears

Finally, NamPower disc brush users can select and use brushing tools to contour parts and avoid smears.

- For part contouring, choose a NamPower disc brush with a longer trim length, finer grit size, and lighter density. Increase the pressure during brushing.

- For a smear-free finish, use a smaller-diameter brush. Decrease the pressure, reduce the spindle speed, and use a coolant.

What else would you like to learn about NamPower technology? For more information about choosing and using NamPower disc brushes, download the NamPower Resource Guide.