High-nickel, iron, and cobalt alloy steels are difficult to machine. These superalloys expose cutting tools to so much stress, strain and heat that tool edges can begin to lose their hardness. When that happens, heavy burrs won’t break off cleanly and work hardening may occur. As Metalworking World magazine explains, outsourced surface finishing may seem like the only option – but that's not the case.

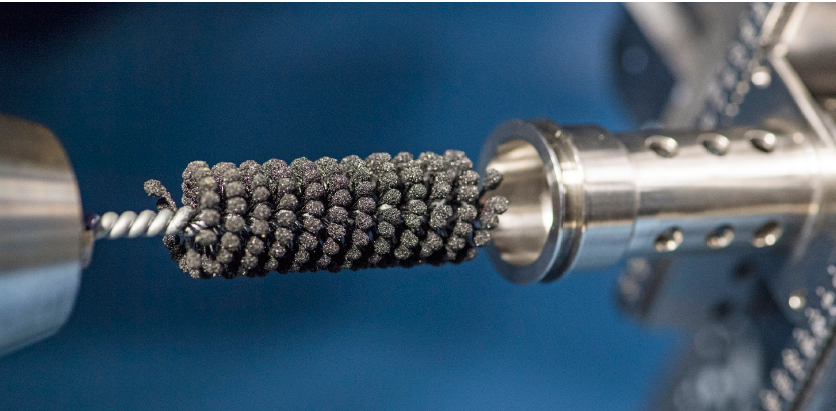

Traditionally, metalworkers used grinding to surface finish machined superalloys. Grinding reduces the risk of oxidation and stress corrosion cracking, but it’s messy, time-consuming, and expensive. By using the CBN Flex-Hone® tool instead, manufacturers and machinists can simplify surface finishing with cubic boron nitride (CBN), one of the world’s toughest, hardest materials. They can keep operations in-house, too.

Until recently, CBN Flex-Hone® tools were available only by special order. Now, these surface finishing solutions for machined superalloys are part of BRM’s standard product line. Learn how to use them with your existing production equipment and read what one machine shop president is saying about them. Download the article from Metalworking World magazine.

.

.