High-performance brake rotors don’t just support braking at high speeds. They dissipate the heat that’s generated at the interface between the brake pad and the brake rotor. Often, members of the performance racing industry choose drilled or slotted brake rotors made of high-quality gray iron or cast iron. Both brake rotor designs have their advantages, but even high-performance brake pads will wear. If friction pad material is transferred unevenly to the surface of the brake disc, noise and vibration can occur.

High-performance brake rotors don’t just support braking at high speeds. They dissipate the heat that’s generated at the interface between the brake pad and the brake rotor. Often, members of the performance racing industry choose drilled or slotted brake rotors made of high-quality gray iron or cast iron. Both brake rotor designs have their advantages, but even high-performance brake pads will wear. If friction pad material is transferred unevenly to the surface of the brake disc, noise and vibration can occur.

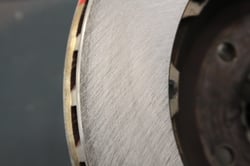

For race industry mechanics, brake jobs can mean more than replacing the pads. Brake rotors need to be replaced or re-surfaced (turned). Fortunately, there’s a surface finishing solution that’s ideal for both new and turned rotors. The Flex-Hone® for Rotors tool from Brush Research Manufacturing (BRM) smooths jagged edges and removes unwanted surface material. BRM’s rotor hone also imparts a unidirectional or “basket weave” that’s perfect for bedding-in new brake pads.

How to Choose Flex-Hone® for Rotors Tools

Flex-Hone® for Rotors tools feature abrasive balls or globules that are permanently bonded to flexible nylon filaments. Brake mechanics can choose coarse, medium, or fine grits depending on the surface finishing challenge. Coarse-grit tools are great for removing sharp edges from slots and holes on new rotors. Smoothing these machined edges makes new brake rotors less prone to cracking. On used rotors, coarse-grit hones can remove heavy build-ups of brake pad material caused by improper bedding.

Flex-Hone® for Rotors tools feature abrasive balls or globules that are permanently bonded to flexible nylon filaments. Brake mechanics can choose coarse, medium, or fine grits depending on the surface finishing challenge. Coarse-grit tools are great for removing sharp edges from slots and holes on new rotors. Smoothing these machined edges makes new brake rotors less prone to cracking. On used rotors, coarse-grit hones can remove heavy build-ups of brake pad material caused by improper bedding.

Coarse-grit tools leave a relatively rough finish, however, so brake mechanics typically follow-up with a medium-grit and then a finer-grit Flex-Hone® for Rotors tool. BRM’s medium-grit rotor hones can also remove old brake pad material, and are usually recommended when build-ups are not severe. Fine-grit Flex-Hone® for Rotors tools provide a like-new surface finish. Race mechanics also use these brake tools to impart an optimum surface finish to new brake rotors.

How to Use Flex-Hone® for Rotors Tools

Flex-Hone® for Rotors tools don’t require special instruction or training. Still, it’s important to use them according to the published guidelines in the Flex-Hone® for Rotors brochure. Secure the tool in a collet, chuck, or similar holding device. Typically, brake mechanics use a variable-speed electric drill or low-speed air drill. As for the brake disc, mount it in a brake lathe and rotate the rotor between 125 and 210 RPM. Remember to position all machine guards and follow all safety precautions.

Flex-Hone® for Rotors tools don’t require special instruction or training. Still, it’s important to use them according to the published guidelines in the Flex-Hone® for Rotors brochure. Secure the tool in a collet, chuck, or similar holding device. Typically, brake mechanics use a variable-speed electric drill or low-speed air drill. As for the brake disc, mount it in a brake lathe and rotate the rotor between 125 and 210 RPM. Remember to position all machine guards and follow all safety precautions.

Then, with the Flex-Hone® for Rotors tool rotating between 300 and 600 RPM, bring the brake hone into contact with the rotating rotor at a slight angle. Work in towards the center and out towards the edge of the rotor face. Use light, uniform pressure for 15 to 20 seconds at a time. Do not use a lubricant, and do not overheat the brake rotor by dwelling for longer periods of time. Typically, 10 to 15 seconds of clockwise honing and 5 to 10 seconds of counterclockwise honing produces the desired surface finish.

Learn More at PRI 2015 (Booth #5513)

Would you like to learn more about the Flex-Hone® for Rotors tool this week? From December 10 to 12, 2015, BRM will be at the PRI Show in Indianapolis. Visit us at the Indianapolis Convention Center in Booth #5513, talk to our Technical Team, and watch videos of our products in action. In addition to the Flex-Hone® for Rotors, you can learn about BRM Flex-Hone® tools for engine cylinders, automotive brushes for engine components, and parts wash brushes for auto parts cleaning.

Are you read you ready to make the most of your PRI 2015 experience. Request a meeting with BRM today.