Engine valves control the flow of fluids and gases in automotive engines. If engine valves fail, the consequences can range from reduced engine power to heat-related part failure. Engine problems can also occur when valve seats, the surfaces against which engine valves rest, lack proper lubrication. Inadequate lubrication increases friction, and friction can cause related engine parts called valve stems to fail.

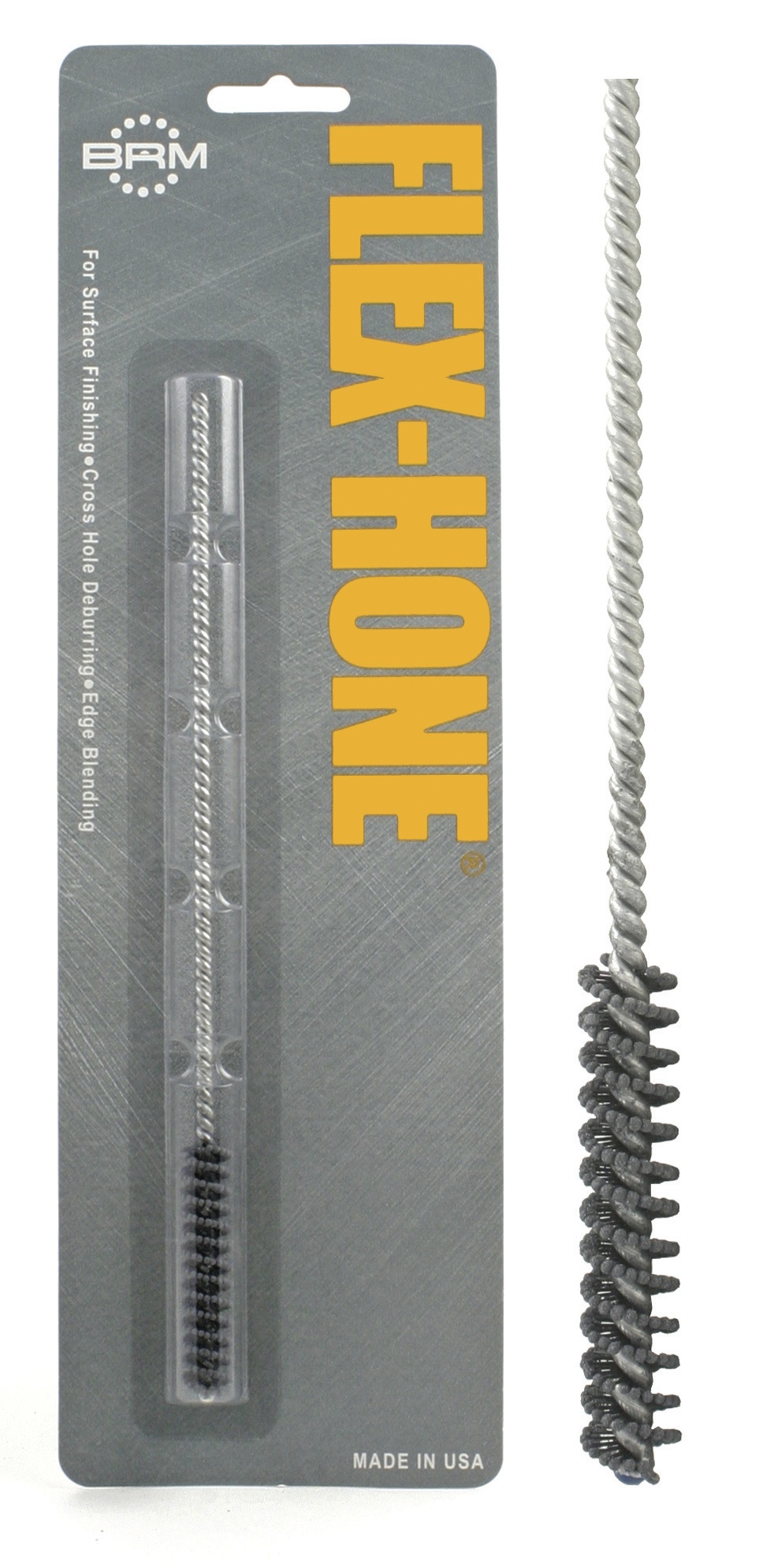

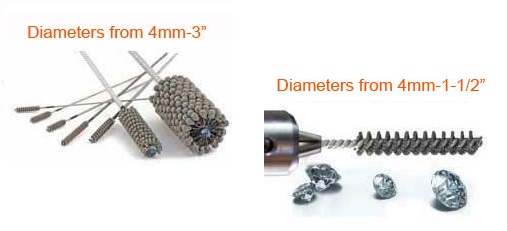

In automotive engines, each intake valve and exhaust valve consists of a cylinder-shaped valve stem and a rounded valve head. Like the engine cylinders in an engine block, valve stems need an oil-retaining surface finish. That’s true for used valve stems that have become worn, and for new valve stems that lack an optimum finish. For these and other surface finishing challenges, the solution is flexible honing.