Wolfram Manufacturing Inc. makes machined metal parts with complex geometries and fine finishes. Like other job shops, the Austin, Texas manufacturer doesn’t want to send out parts for surface finishing and deburring. When lead times are short and profit margins are tight, outsourcing this work doesn’t make good business sense. Yet many metal fabricators need to meet tight tolerances every time..

Flex-Hone® for Tight-Tolerance Parts Saves Manufacturer Time and Money

Topics: Flex-Hone, surface finishing, deburring, machined parts

Flex-Hone® Reduces Roughness and Promotes Sealing in Anodized Cylinders

Anodizing imparts a wear-resistant coating to cylinders. This electrochemical process permits the use of lightweight aluminum instead of heavier metals, but anodizing increases surface roughness. Moreover, anodizing increases a cylinder’s outer diameter (OD) while decreasing its inner diameter (OD). These changes in surface quality and dimensions can interfere with parts mating and sealing.

Topics: Flex-Hone, surface finishing, anodized cylinders

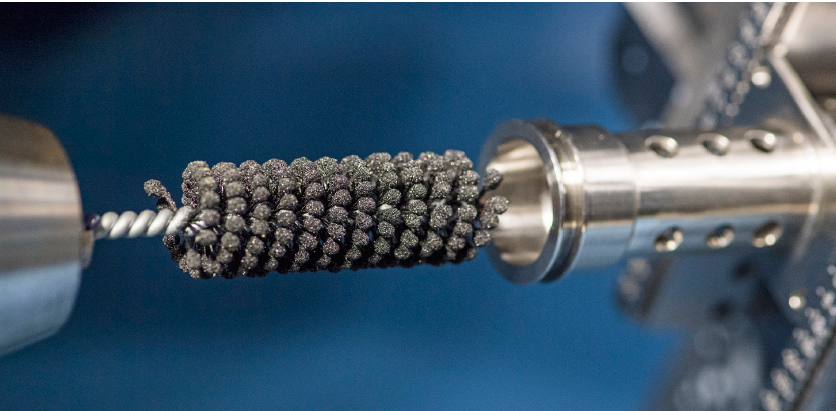

Machined Superalloys Get Better Surface Finishing Tools

High-nickel, iron, and cobalt alloy steels are difficult to machine. These superalloys expose cutting tools to so much stress, strain and heat that tool edges can begin to lose their hardness. When that happens, heavy burrs won’t break off cleanly and work hardening may occur. As Metalworking World magazine explains, outsourced surface finishing may seem like the only option – but that's not the case.

Topics: Flex-Hone, cbn flex-hone, surface finishing, machined superalloys

Planar honing imparts a fine finish to flat surfaces like sliding guideways, machined metal parts that support linear motion. Traditionally, machine tool sliding guideways were made of hardened cast iron and fabricated with cubic boron nitride (CBN) milling tools and grinding. As Grinding & Surface Finishing magazine explains, however, there’s another way to improve sliding guideway surface finish.

Topics: Flex-Hone, planar honing, flex-hone for rotors, plateau finishing

Cross-hole deburring can be tedious and time consuming. It's not easy to remove sharp edges from grooves, undercuts, slots or internal holes either. For precision parts, however, it's essential to have smooth, round edges. Components with hard-to-access features need a close-tolerance surface finish, too.

Threaded parts with diameters less than 0.125 in. are hard to deburr. That’s because the rough edges or ridges left by machining are so small. Heavy nylon deburring tools or butterfly brushes are fine for larger threaded components, but what about the microburrs on smaller threaded parts? They need precise polishing rather than aggressive deburring.

The Pontiac Firebird Trans Am was an iconic muscle car with a reputation for speed and flair. In 2002, the Trans Am’s final year of production, Pontiac powered its pony car with an 8-cylinder, 16-valve, 5.7-liter, 347-cubic inch engine called the LS1.

Even today, restoring this all-aluminum engine block is a labor of love. As ls1tech.com, an automotive website, a mechanic shared a story that’s familiar to many do-it-yourselfers (DIYers). For surface finishing cylinder walls, there’s no substitute for BRM Flex-Hone® tools.

Topics: Flex-Hone, Automotive

Shotgun chambers need a smooth, polished finish so that spent shells eject properly. The bore’s surface may look shiny, but there’s more to chamber honing than the mirror-like finish that meets the eye.

For best results, a shotgun chamber needs a plateau finish with a uniform series of peaks and oil-retaining valleys. This substantially smooth surface finish reduces friction and fouling while promoting optimum lubrication.

Some gun owners have heard of plateau finishing, but the phrase “slicking up” might be better-known. In Slicking up the Stoeger S x S Shotgun Part III, an on-line article about shotgun chamber honing, the owner of a Stoeger Silverado Coach Gun described the power of plateau finishing with Flex-Hone® for Firearms tools. “Those shells will easily come out of the chambers now,” the gunsmith explained.

Topics: flex-hone for firearms

Bearing bores are engine components that house the main bearings, mechanical elements with grooves for passing oil to feed-holes in the crankshaft. For optimum engine performance, bearing bores or tunnels must meet tight tolerances and have an oil-retaining surface finish.

Line boring with a rigid hone is the right choice for bores that are out-of-round or that require significant material removal. To impart an oil-retaining final finish, however, automotive experts like MSB Tuning in Queensland, Australia recommend the “world’s best cylinder bore” – the BRM Flex-Hone® tool.

Topics: Flex-Hone, Automotive

Engine cylinders need a substantially smooth surface finish that’s free from cut, torn, and folded metal. Yet cylinder walls can be so smooth that engine performance suffers.

Over time, the up-and-down movement of pistons creates an overly smooth surface finish. Piston rings skate along cylinder walls and fail to seat and seal properly. The “glaze” that forms can also prevent engine oil from adhering properly.

The solution to these challenges is the Flex-Hone® tool from Brush Research Manufacturing (BRM). This Made in the USA glaze-breaker hone removes burrs, deglazes cylinder walls, and improves surface finish at the same time. That’s why bloggers like The Bug Boys use BRM Flex-Hone® tools for engine rebuilds.

Topics: Flex-Hone, Automotive