Cross-hole deburring can be a big problem for manufacturers of small metal parts, especially when hole diameters are just a few millimeters or a fraction of an inch. Manual deburring is common, but it’s also labor-intensive and can yield inconsistent results. Automated deburring is faster and more uniform, but automation alone isn’t the answer.

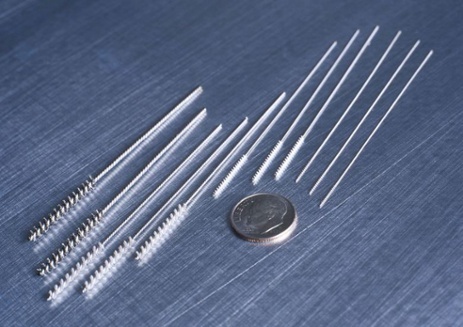

Manufacturers who deburr small metal parts need more than just the right personnel and equipment. With cross-drilled holes, it’s especially important to use deburring tools that impart a burr-free, high-quality surface finish. As a full-line manufacturer of flexible honing tools and industrial brushes, Brush Research Manufacturing (BRM) has the solution.