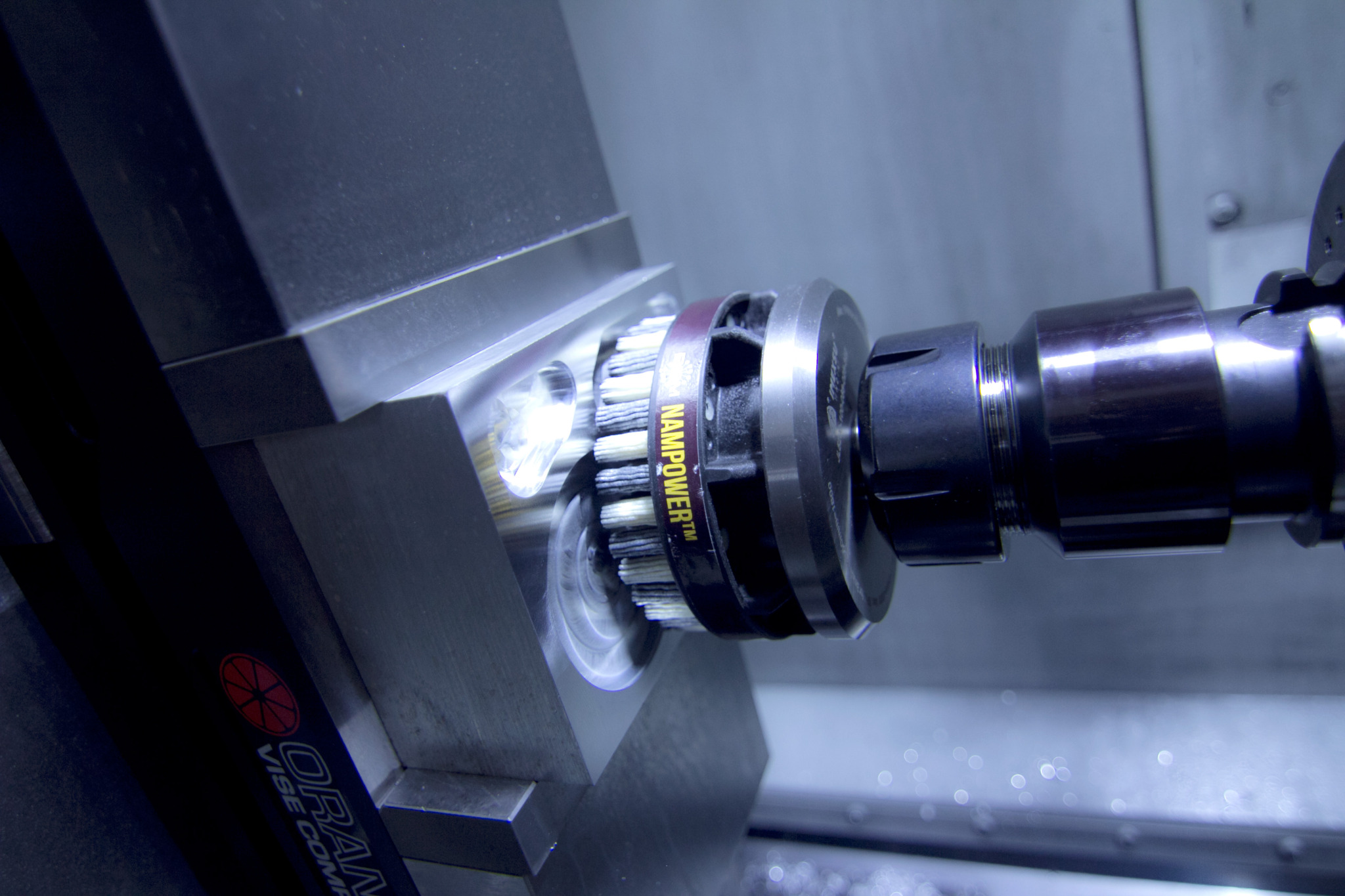

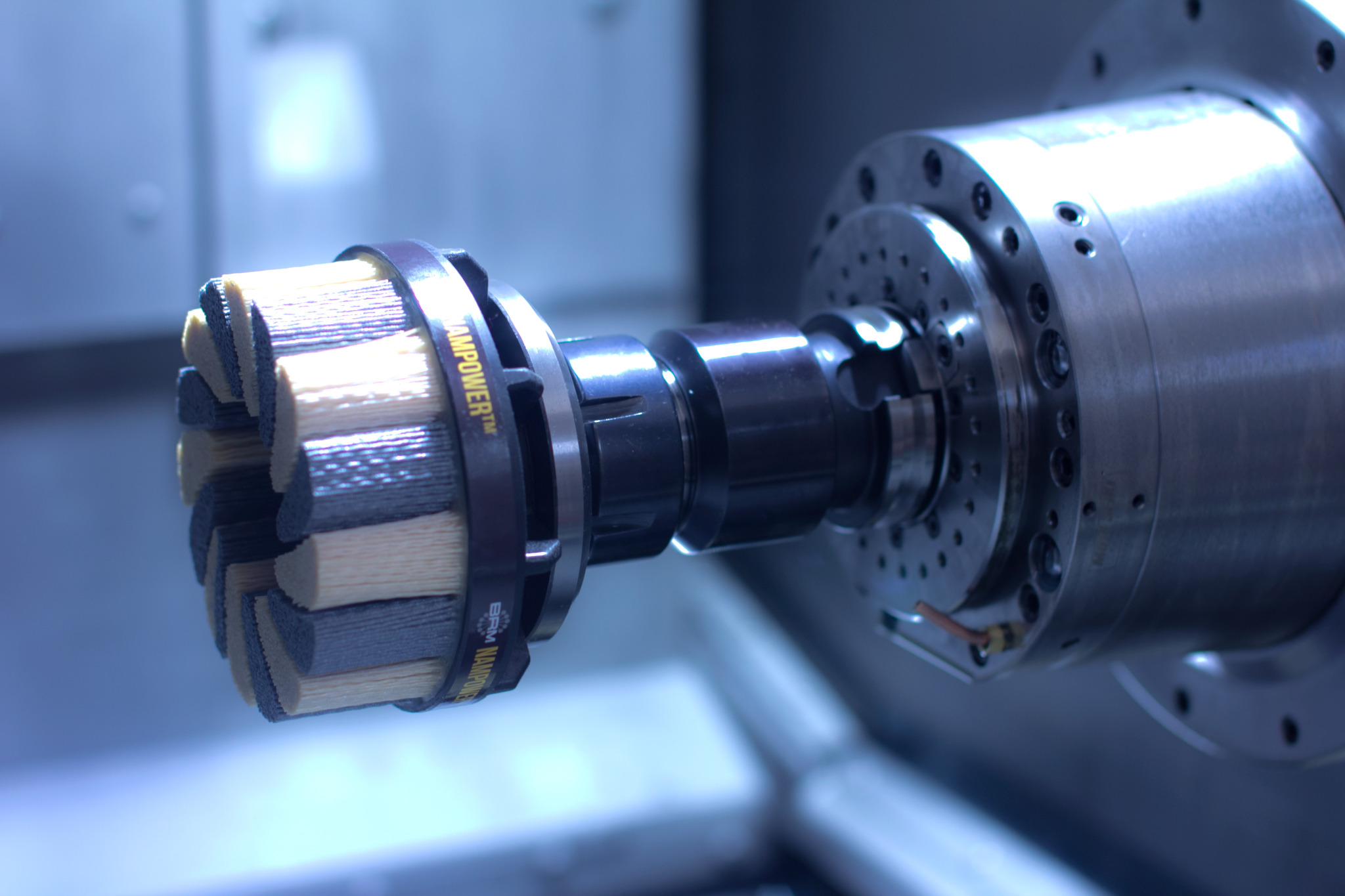

Small-diameter Flex-Hone® tools are a great choice for imparting a smooth, oil-retaining surface finish to the walls of smaller-diameter cylinders. These miniature metalworking tools from Brush Research Manufacturing (BRM) can also remove burrs from cross-drilled holes.

Flexible honing requires no special training or instruction, but which small-diameter Flex-Hone® tool do you need? Bore size is important, of course, but you’ll also need to consider the workpiece base material and the amount of work to perform.