Do you or your customers need solutions to surface finishing challenges? Are you looking for the right tools and technologies to remove burrs and improve surface quality? If you’re ready to find answers to your most challenging surface finishing questions, Brush Research Manufacturing (BRM) is ready to help. As a full-line supplier of flexible cylinder hones and industrial brushes, BRM does more than supply products. With our 55 years of experience, we provide technical expertise like you’ll get with our Tech Lab program.

Topics: Send In Your Part

NamPower Abrasive Disc Brushes: Application Guidelines

NamPower abrasive discs are high-performance brushing tools for automated deburring and surface finishing. Their unique combination of ceramic and silicon carbide abrasive produces maximum burr removal rates and an optimum surface finish at the same time. Designed for use with today’s machinery, these abrasive disc brushes integrate easily with CNC machining centers, transfer lines, and robotic cells.

As a full-line supplier of surface finishing and deburring tools, Brush Research Manufacturing (BRM) offers NamPower disc brushes in different styles, diameters, trim lengths, and grit sizes. During disc brush selection then, manufacturers need to consider all of these product specifications. During brush tool use, application guidelines for aggressiveness, contouring, and fine or coarse finishing should be considered.

Topics: NamPower Abrasive Disc Brushes

Rusty brake rotors don’t just look bad. Corrosion can cause uneven or premature wear to your brake pads. Rust can also promote the excessive build-up of heat, which can cause brake rotors to warp. From friction-induced brake noise to that annoying, pulsing feeling in the steering wheel, brake shop mechanics hear their share of complaints. So what’s the best way to solve brake rotor problems?

Topics: Brake Rotors

Power brushes are handheld or machine-based brushing tools for surface preparation, deburring, and surface finishing. Applications include edge blending, weld cleaning, rust or paint removal, parts polishing, and wire stripping.

As their name suggests, power brushes are designed for use under power. Depending upon the brush type and application, they can be used with a high-speed handheld tool such as an electric drill, or with machinery and equipment such as a bench or pedestal grinder. Many different types of power brushes are available, but buyers need to consider more than just brush type.

Topics: Industrial Brushes

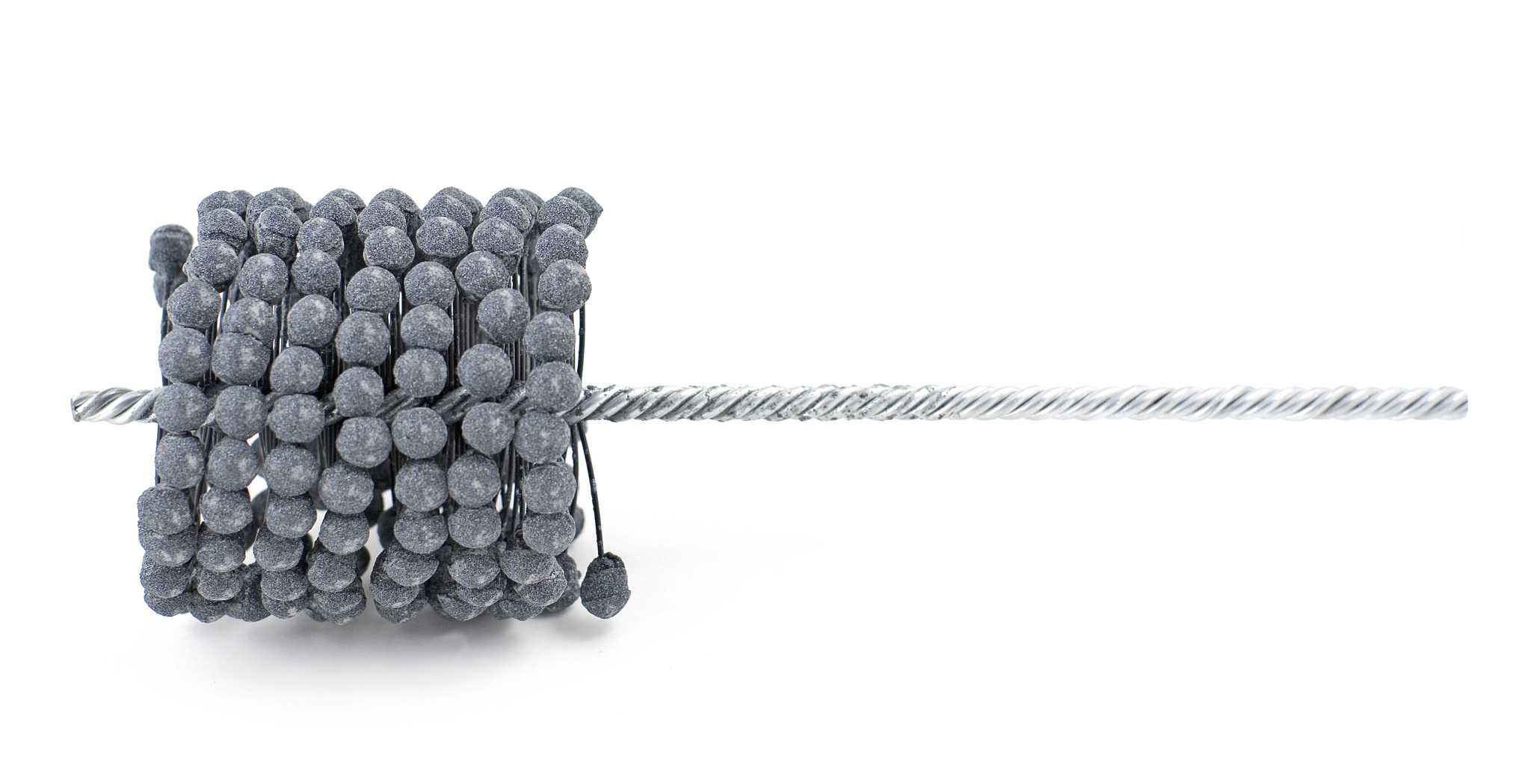

Miniature Deburring Brushes for Smaller Cross-Drilled Holes

Small cross-drilled holes can pose significant deburring challenges for parts manufacturers. Cross-drilling creates burrs, protrusions of cut, torn, folded, and jagged metal that can affect dimensional tolerances, cause part misalignments, and limit the overall efficiency of machined components.

Different cross-hole deburring technologies are available, but manual burr removal can be labor-intensive. For industries such as medical device manufacturing, part quality and consistency are also essential.

Topics: Industrial Brushes

Some drag racers tune or rebuild OEM engines. Others install aftermarket powerplants like the Chevy LSX, a cast-iron racing block with engine displacements ranging from 364 to 511 cubic inches. Built for serious horsepower (hp), the LSX can support over 2,000 hp in forced induction applications. Perhaps not surprisingly then, this replacement engine was designed with some help from drag racing legend Warren Johnson, the winningest driver ever in the National Hot Rod Association (NHRA) Pro Stock class. Today, high-compression bowtie blocks like the LSX454R deliver a whopping 770 hp.

Police shotguns have shorter barrels and larger magazine capacities than hunting shotguns. Although a sawed-off shotgun may have a shorter effective range, firearms with reduced-length barrels are easier to maneuver, conceal, and store. For law enforcement officers (LEOs) on patrol, these so-called riot shotguns also support police operations such as entry and breaching. With any type of weapon, however, it’s not just marksmanship that’s linked to performance. Gun maintenance also matters.

Topics: Firearms Maintenance

Surface Finishing Tips for Steel Wire Wheel Brushes

Metal fabricators use steel wire wheel brushes for surface preparation, surface finishing, burr removal, weld cleaning, and rust and oxide removal. Wheel brushes with steel filaments aren’t just versatile, however. They’re also dependable. For example, steel wire tips remove contaminants, coatings, and surface imperfections without changing part dimensions. Steel wire brushes are also non-loading, which means that they won’t become clogged with debris.

Flexible Cylinder Hones for Field Equipment Repairs

Would you rather spend $30,000 to replace damaged cylinders, or would you rather repair them with a tool that costs less than $200 and is easy-to-use? If you offered this choice to your customers, what would they say? Would they happily spend thousands of dollars to replace equipment they’d never even used, or would they give your company credit for solving a surface finishing problem in a smart, efficient, cost-effective way?

Would you rather spend $30,000 to replace damaged cylinders, or would you rather repair them with a tool that costs less than $200 and is easy-to-use? If you offered this choice to your customers, what would they say? Would they happily spend thousands of dollars to replace equipment they’d never even used, or would they give your company credit for solving a surface finishing problem in a smart, efficient, cost-effective way?

Ask Elmar Industries, a manufacturer from Depew, New York that makes filling machines for sanitary applications. Elmar’s rotary piston equipment is a shining example of precision machining. The company’s 45-station piston filler dispenses a metered quantity of product, and the tolerance between each valve and valve housing must be within 0.001 in. Elmar manufactures filling machinery to the highest quality standards, but equipment suppliers can’t control accidents that happen on a customer’s factory floor.

Topics: Cylinder Honing

Firearms Maintenance for Model 1917 Colt .45 Revolvers

The Model 1917 Revolver is a six-shot .45 ACP caliber sidearm with moon clips for holding rimless cartridges in position. Star-shaped and made of thin metal, a moon clip works like a cartridge rim by setting the headspace for a chambered cartridge. M1917 revolvers made by Colt and Smith & Wesson were chambered for .45 ACP ammunition, but can also fire rimless .45 Auto Rim cartridges.