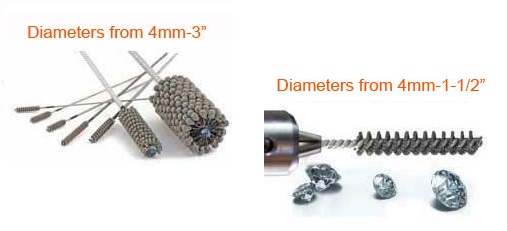

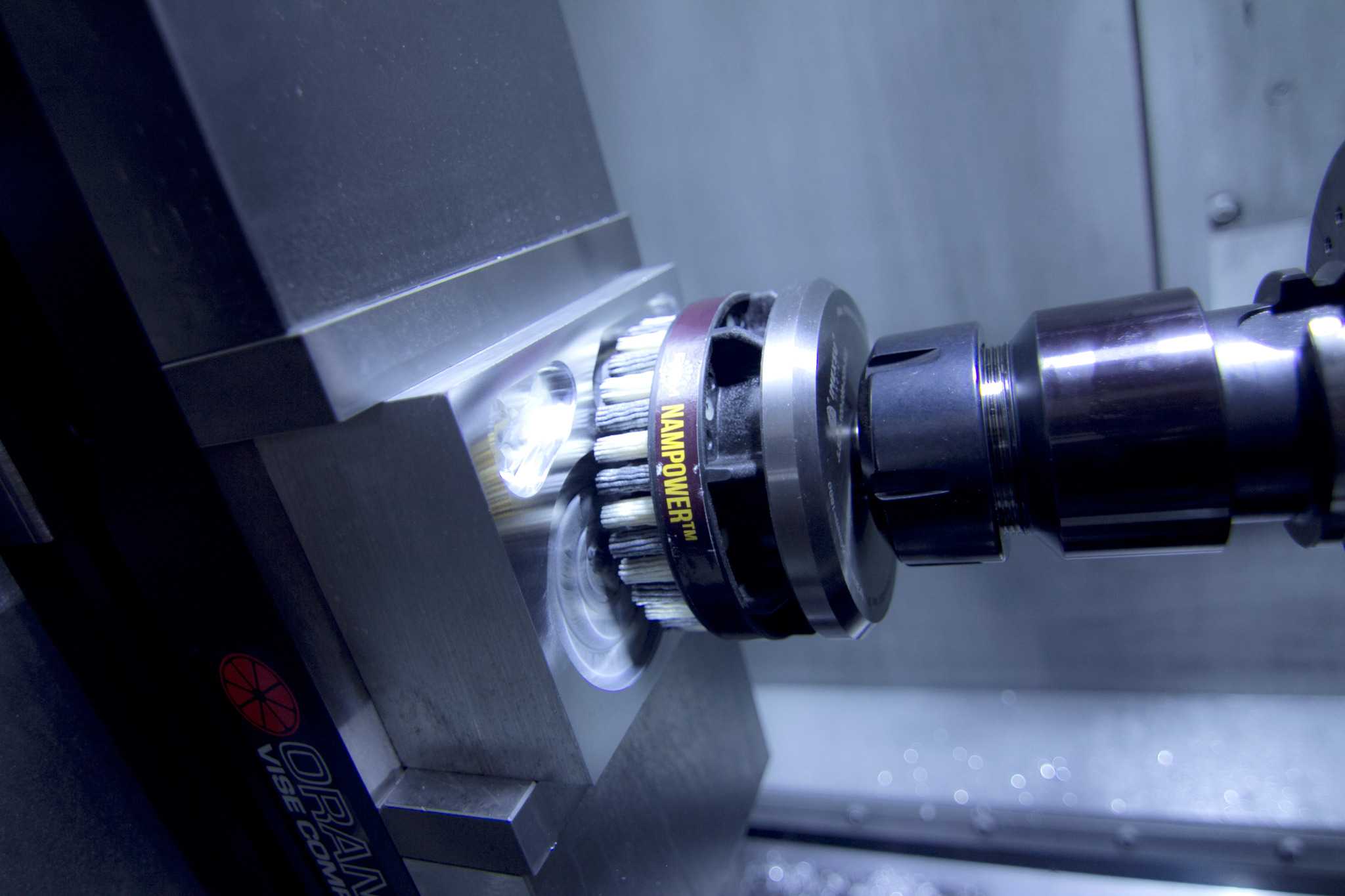

Brush Research Manufacturing (BRM) supplies many different Flex-Hone® tools for surface finishing and deburring small-diameter cylinders. These flexible cylinder hones are grouped into BC and Diamond Flex-Hone® categories, and then specified by tool diameter, abrasive type, and grit size or mesh.

All Flex-Hone® tools are Made in the USA and can be ordered via BRM's website or through our vast network of national distributors. These surface finishing and deburring tools are also available through the American-owned company’s global distributor network as well. So which small-diameter Flex-Hone® tools do you need? Let's take a look at BC Series and Diamond Flex-Hone® tools, and examine how to order and use them.