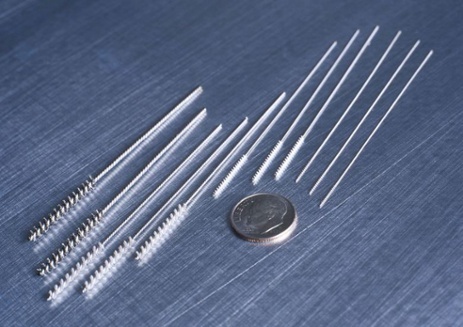

Miniature deburring brushes help keep small-diameter holes from becoming big-time finishing problems. These miniature metalworking tools remove small burrs that can cause part misalignments. They also perform internal cleaning and produce the proper edge radius on machined holes with small diameters.

Brush Research Manufacturing (BRM), maker of the Flex-Hone® tool, supplies different types of miniature deburring brushes. These tools can be driven by hand or used under power, but there are some basic operating instructions that you need to follow. Here are some tips for selecting and using these tools.