FABTECH is North America's largest metal forming, fabricating, welding, and finishing event. With thousand of exhibitors and tens of thousands of attendees, FABTECH is where metal fabricators and and manufacturers find the tools and technologies they need.

Are you headed to FABTECH 2015 next month? Do you need surface finishing and deburring solutions? Don't wait until you arrive to plan your time on the tradeshow floor.

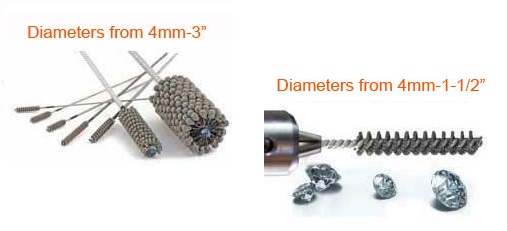

Request a meeting with Brush Research Manufacturing (BRM) in Booth #N-10088 at Chicago's McCormick Place from November 9 to 12, 2015. Here's what to expect when you meet with the BRM Team.