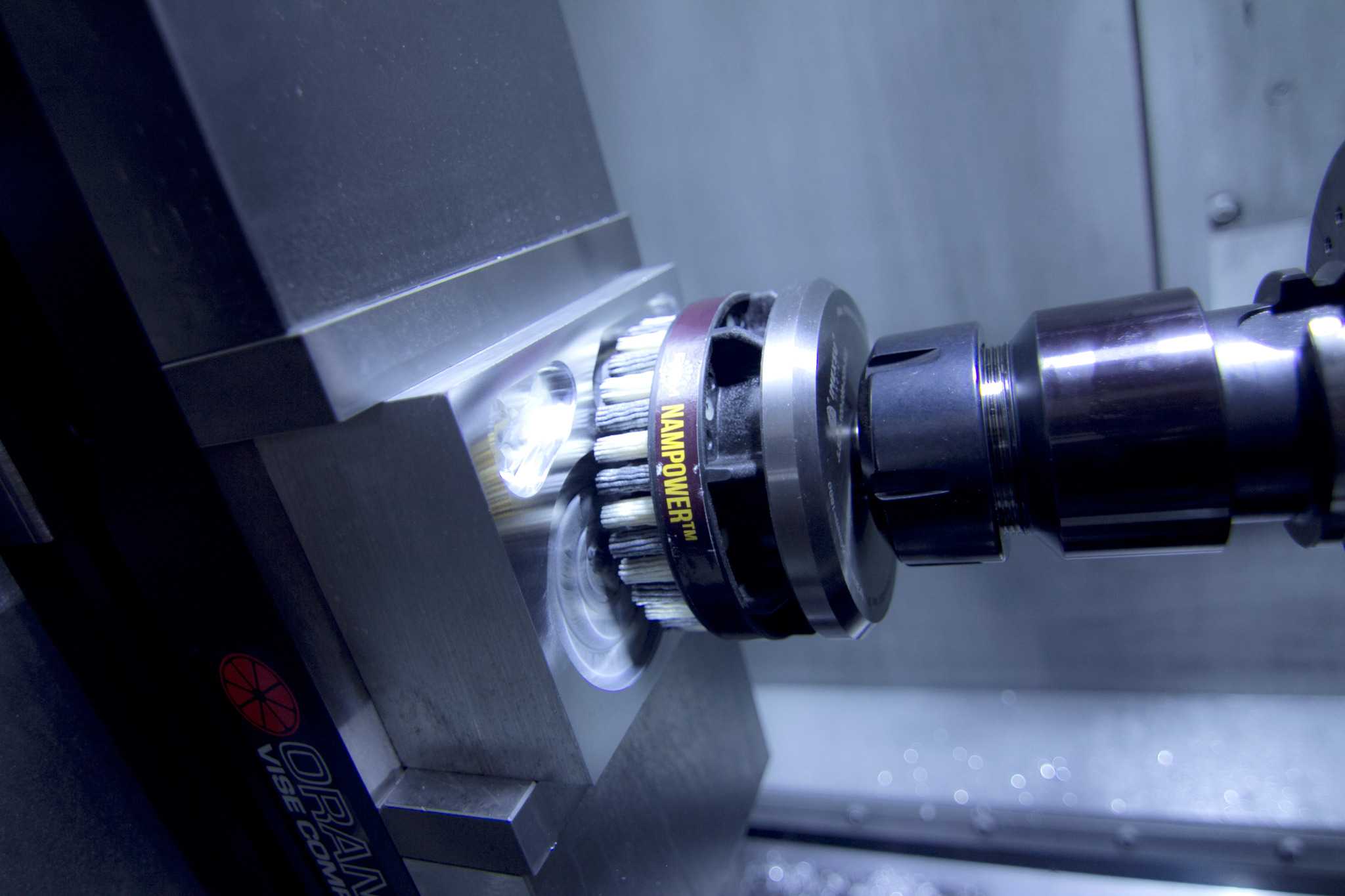

Are you looking for diamond tools that can deburr harder materials and improve surface finish? As a full-line supplier of surface finishing technologies, Brush Research Manufacturing (BRM) provides diamond honing tools, diamond wheel brushes, and miniature diamond deburring brushes to leading manufacturers and a global network of distributors. BRM keeps flexible hones and brush tools in stock, ships products within 24 hours, and can offer expert advice. Which type of diamond tool do you need?