The Brush Research Manufacturing (BRM) Blog is ending the year by looking back at how we’ve helped readers find solutions to surface finishing challenges.

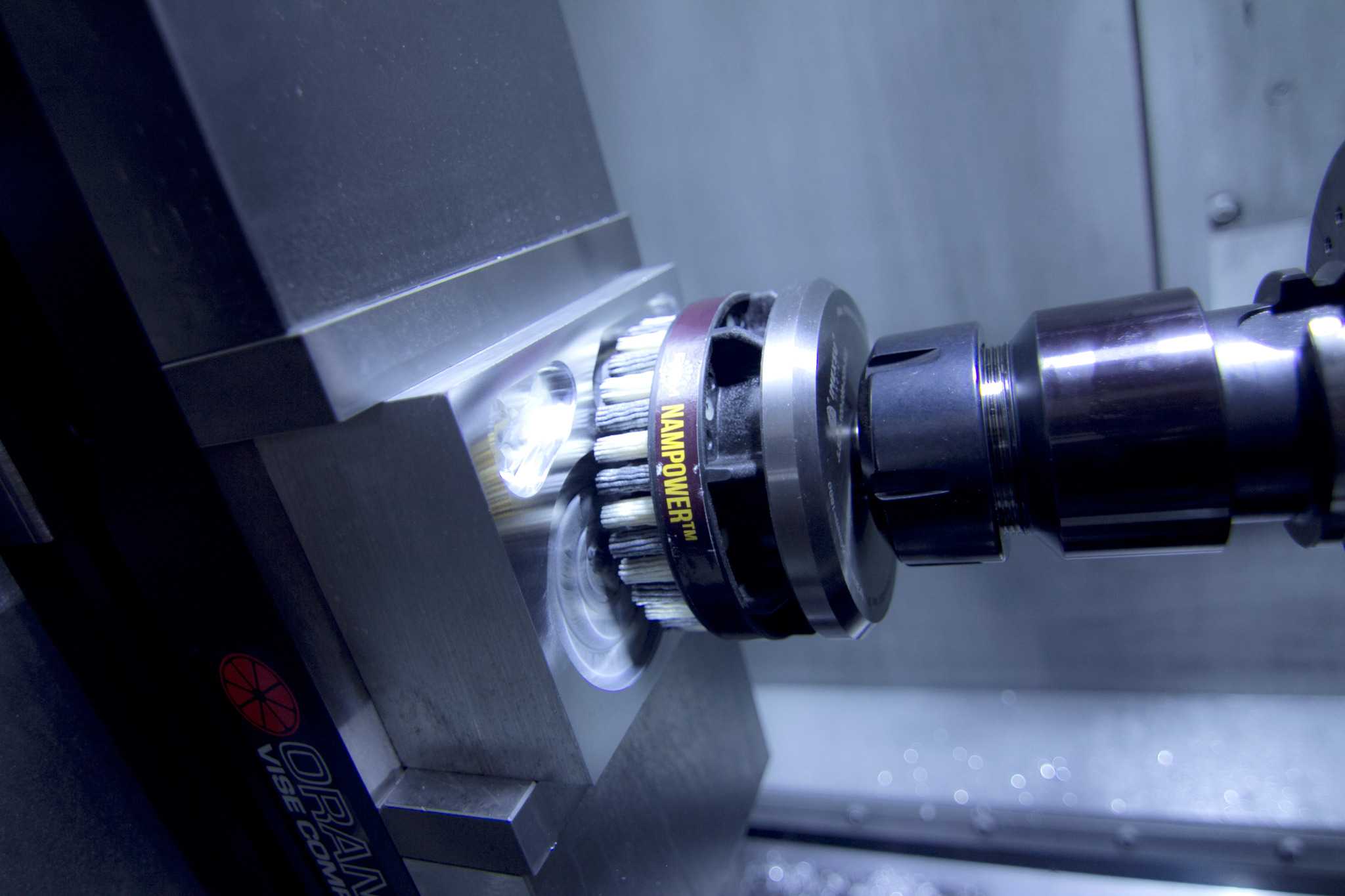

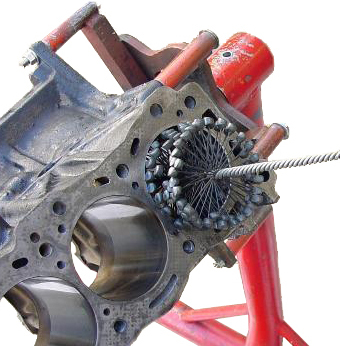

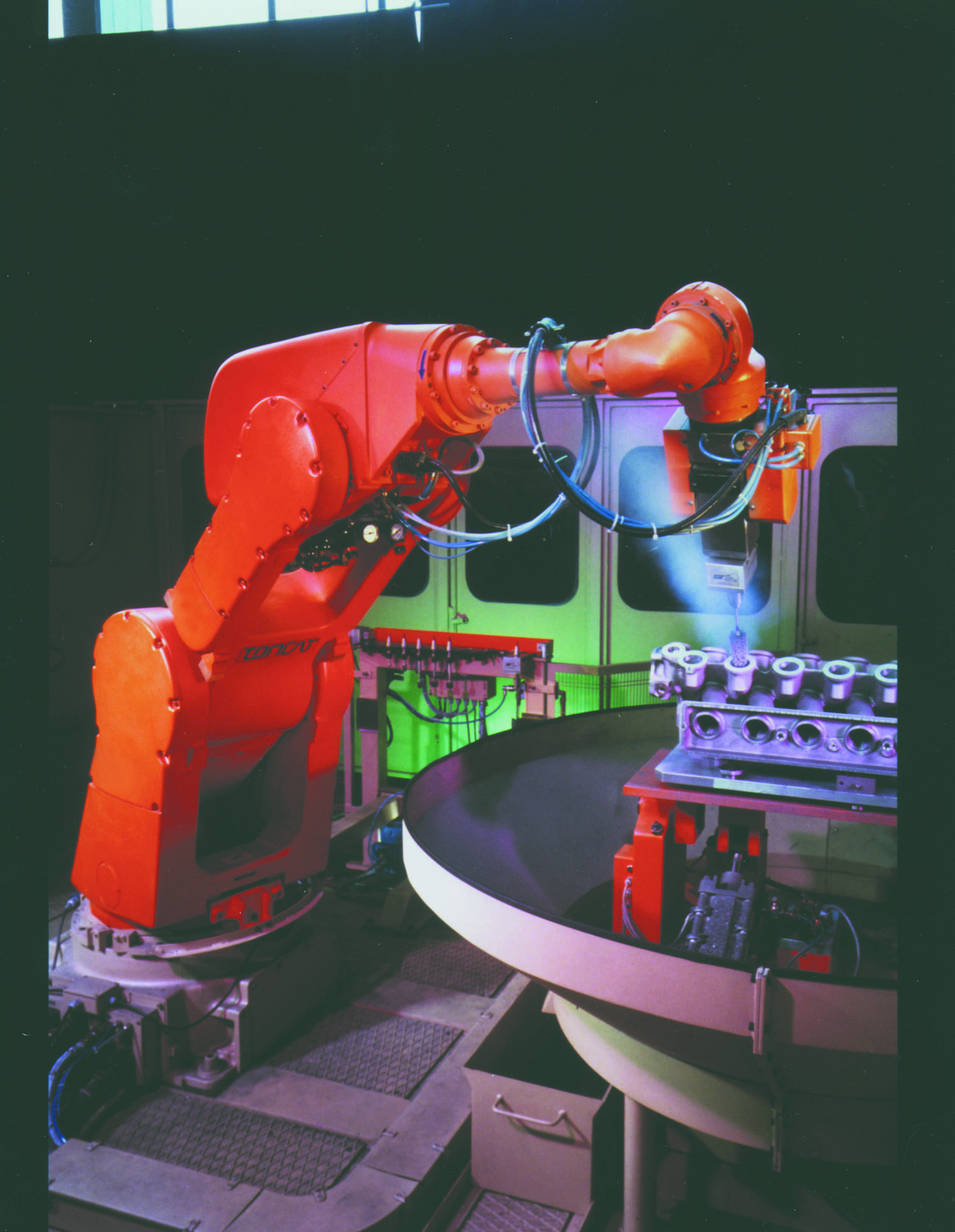

As a full-line manufacturer of flexible honing tools and industrial brushes, we’ve covered plenty of topics in 2015. Here are our Top 5 Blog Posts for the year. We hope you’ll enjoy this look back, and we look forward to sharing more great content with you in 2016.