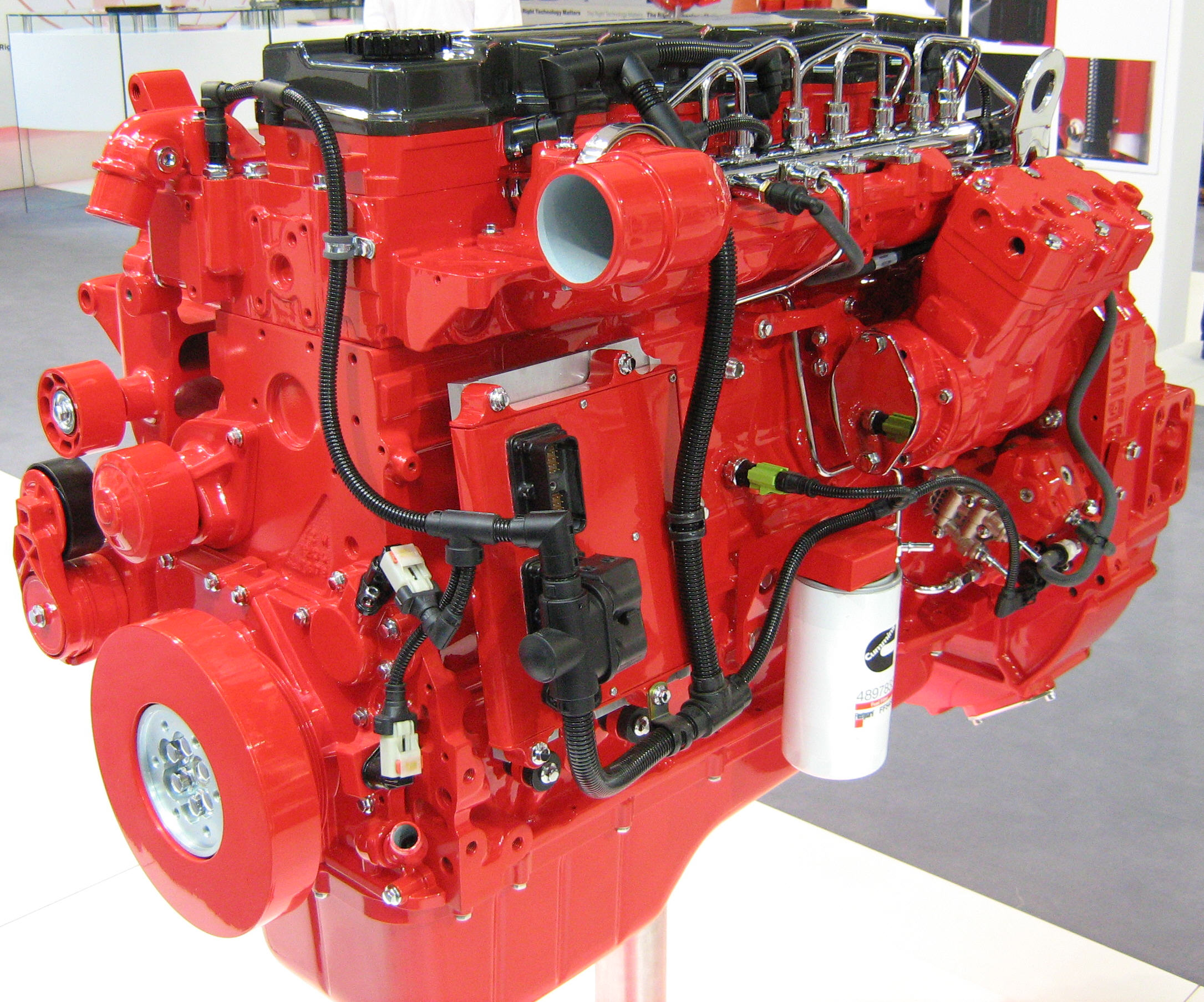

Part manufacturers use a variety of methods to produce through-holes for fasteners. For example, in the aerospace industry, techniques such as drilling, milling, and reaming are used with metals such as nickel, Inconel, Waspalloy, titanium, and stainless steels. Unless these hole-drilling and edge-breaking processes are performed perfectly, however, machined parts may not meet demanding aerospace specifications.

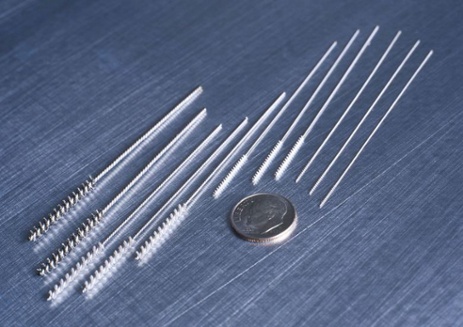

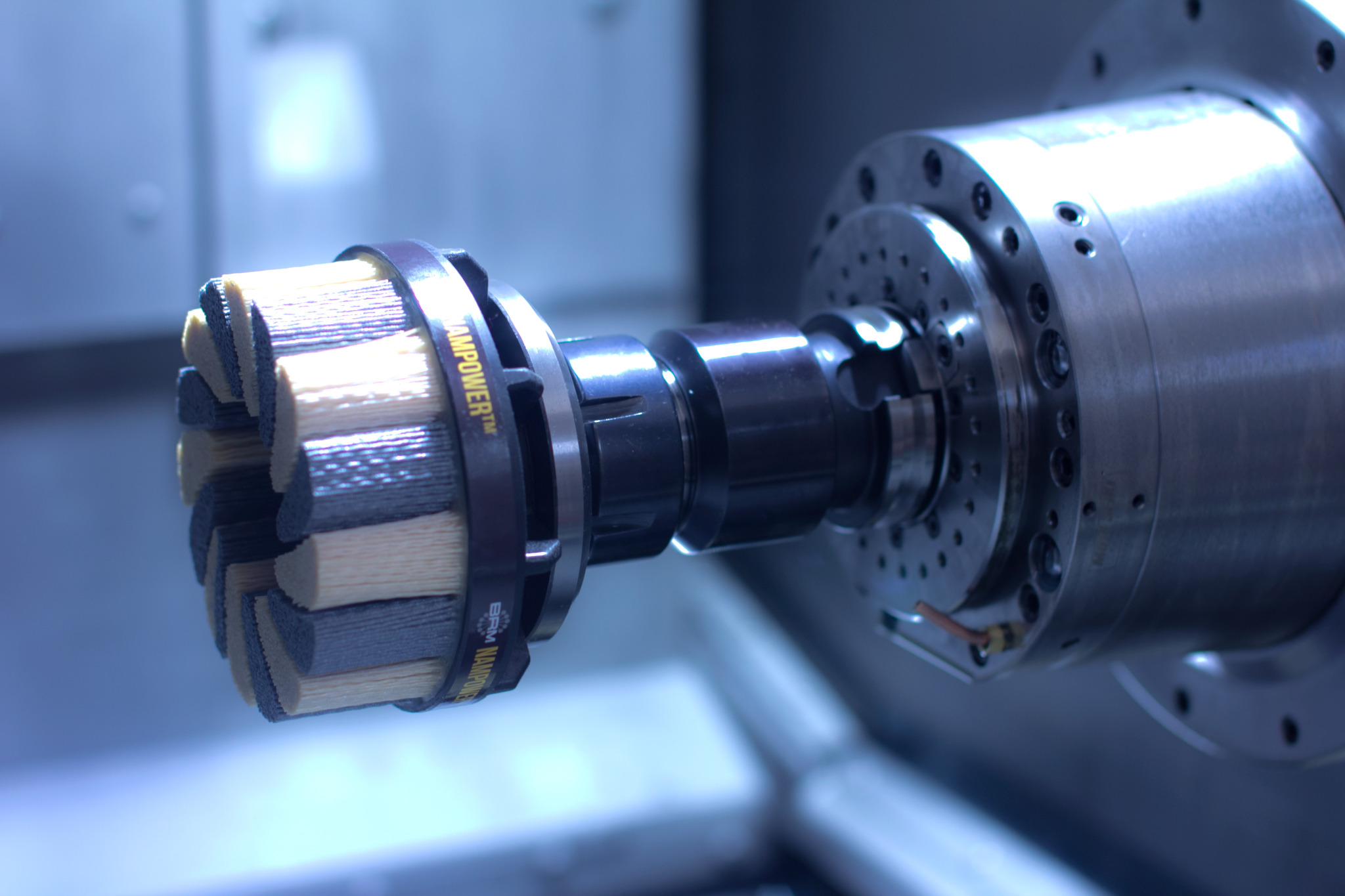

Manufacturers in the automotive and semiconductor industries also face challenging requirements for surface quality. To produce through-hole surfaces that are chamfered, free of burrs, and have radiused edge transitions, metalworkers need to select and use the best surface finishing and deburring tools. For final parts deburring and finishing, industry leaders trust the Flex-Hone® for Chamfer Blending.