Do you need to clean auto parts such as oil pumps, wheels and wheel bearings, lug nuts, or engine and brake components? What about machined parts such as valves and gears?

Do you need to clean auto parts such as oil pumps, wheels and wheel bearings, lug nuts, or engine and brake components? What about machined parts such as valves and gears?

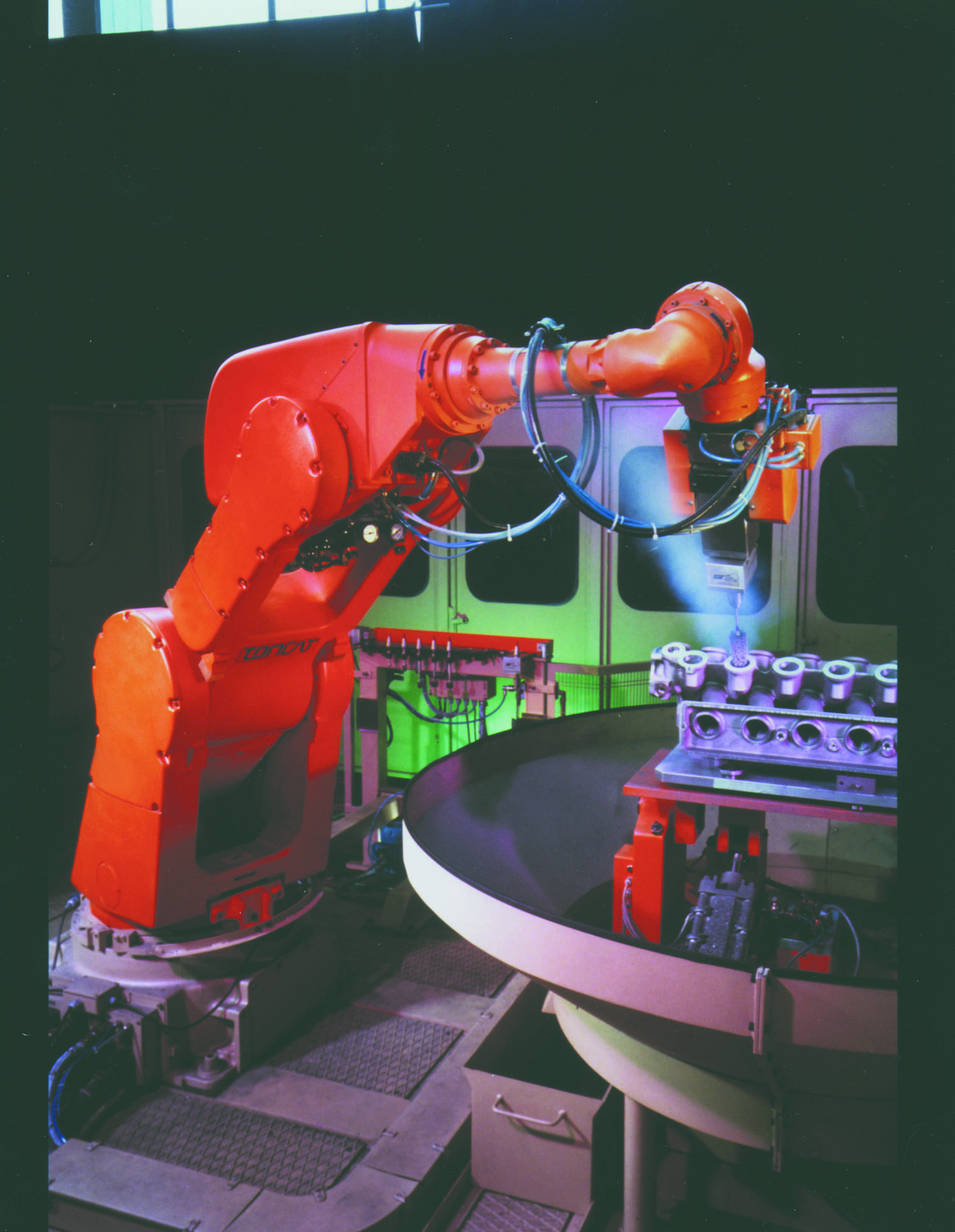

Parts wash brushes from Brush Research Manufacturing (BRM) speed parts cleaning operations, saving you time and money. Their long-lasting synthetic filaments resist solvent-type cleaners, and these cost-effective cleaning tools are great for removing cutting fluids, machine oils, lubricants, grease, road grime, and dirt.