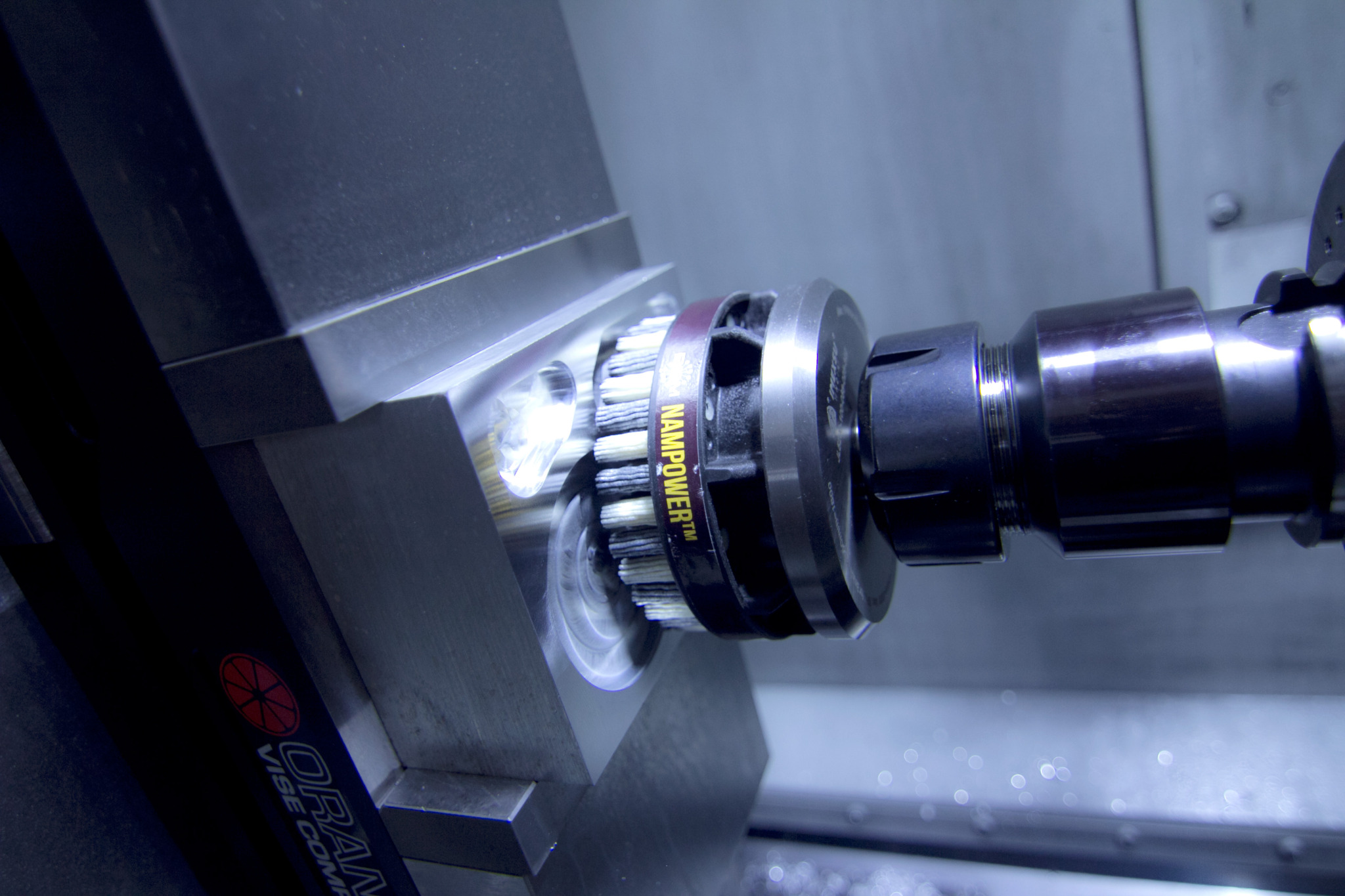

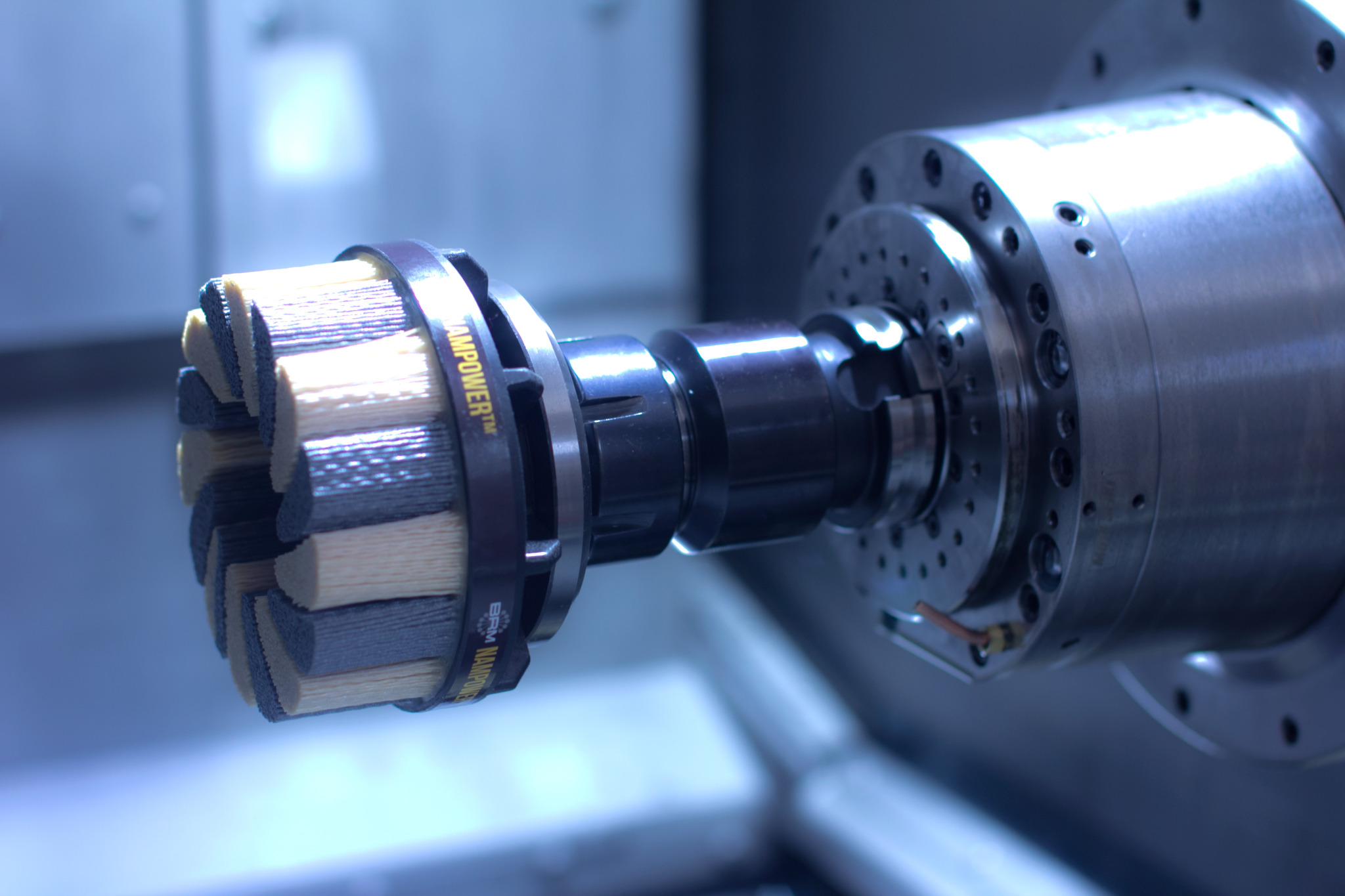

NamPower disc brushes are nylon abrasive brushing tools for surface finishing and deburring machined components. They feature a unique combination of ceramic and silicon carbide abrasive for maximum burr removal and efficient surface improvement. NamPower discs can help you to improve part quality and consistency, but which type of tool do you need for your application?

Brush Research Manufacturing (BRM) supplies NamPower disc brushes in different styles and sizes. The NamPower Resource Guide provides complete information about tool selection and use, but here’s what you need to know about achieving finer or coarser finishes. There are four main factors to consider: trim length, disc speed, grit size, and coolant use. For coarser finishes, you may need a smaller-diameter tool, too.