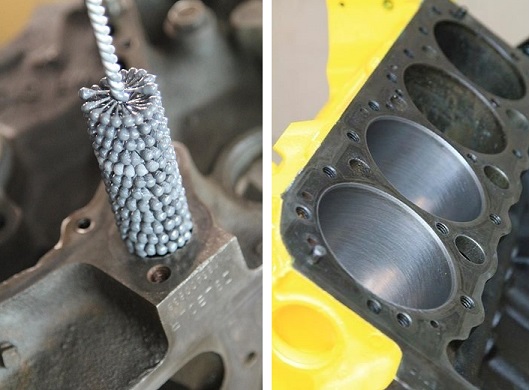

Most brake rotors get resurfaced when old, worn brake pads are replaced. By the time a vehicle needs a brake job, the rotors may have grooves or areas of wear from the rubbing of the old pads. If a brake rotor has an uneven surface, the new pads won’t make contact with the rotor at the proper angle – and squeaking or squealing may result. Even with new OEM or aftermarket rotors, a factory finish that’s less than ideal may cause brake noise.

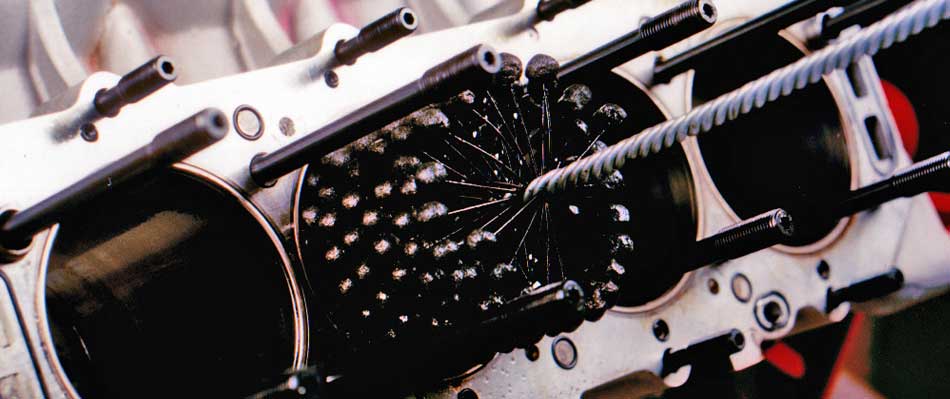

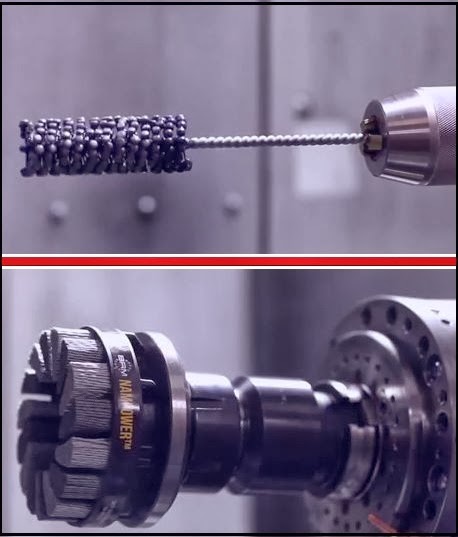

To improve the surface finish of brake rotors, auto mechanics trust the Flex-Hone® for Rotors tool from Brush Research Manufacturing (BRM). Named an Undercar Digest Magazine Top Ten Tool for 8 years in a row, BRM’s rotor hone imparts a non-directional surface finish where “scratches” on the rotor’s surface extend in various directions. This “basket weave” finish doesn’t just help the new pads to seat properly. It lowers harmonic vibrations and reduces noise.